While mass-produced, blockbuster drugs have changed the world, they can be inefficient. Many work on only half their target population; others require recalls due to adverse effects in certain individuals or sub-populations that were not seen in trials. Precision medicine – drugs tailored to smaller populations or even to individual patients – is the answer. But even as more companies take up the task of designing and developing new targeted medicines, they must face a significant challenge in the manufacturing of these small-run, customised products.

Precision medicine, the adaptation of treatments to better suit a particular patient or sub-population, relies on a better understanding of the factors that lead to patient symptoms, from genetics to diet.

Beyond ensuring better preventative care for patients, precision medicine also lets clinicians reduce the danger of adverse drug effects, e.g. unwanted negative effects of taking a certain product. By better understanding the needs of an individual patient or smaller sub-population, drugs and prescriptions can be tailored to suit the needs of the individual, rather than providing a ‘one size fits all’ solution that ignores age, sex, and other miscellaneous variations between individuals.

The implications of personalised medicine in manufacturing

The rise of personalised medicine naturally garnered an interest in the ability to make more targeted drugs for smaller patient populations. This has a number of benefits for pharma companies, in particular the ability to target areas and indications that few other companies are involved in, thus raising the potential for successful drug development by avoiding the overcrowded areas of common targets.

But there are also several downsides or challenges to this approach – namely the additional costs and research efforts that must go into manufacturing drugs for smaller populations, with profits decreased due to smaller patient populations – despite more of the cost being passed on to third-party payers and the patients.

In addition to cost, the manufacturing needs of these high-cost, complex drugs are higher, with more flexibility needed in order to work around the small manufacturing numbers.

Mass production

Traditionally, pharma manufacturing has relied on a push model, e.g. demand is reviewed ahead of time and inventory supplied to that demand. With precision and personalised medicine, a considerably more tailored and made-to-order approach must be taken due to the smaller patient population, with clinics and hospitals providing diagnostic information and requesting a set amount of supplies.

Manufacturing the small batch numbers needed for personalised medicine requires a large number of changes compared with batches of mass-produced, more generalised drugs. Due to a shorter production time, any product changeover time becomes a much larger issue in relation to the overall time of production, and can lead to a loss of profit due to the changeover and extreme inefficiencies involved.

To solve this problem, separate and more flexible lines are preferable, operating alongside large-capacity lines to ensure less changeover and overall much greater efficiency.

With the need for multiple product lines comes an increased cost of equipment and processes. This will affect the pockets of many smaller pharma and biotech companies, and it is highly possible that increased outsourcing of pharma manufacturing will result as these companies find partners who can provide that tailored, flexible line for the smaller product.

In another effort to reduce costs in the manufacturing of more specialised medicines, downstream activities including filling are being streamlined to reduce waste. New equipment and solutions limit the waste of product enormously, with non-destructive inline weight checkers reducing loss from nonconforming vials or overfilling by a large amount. Newer isolator technology also ensures better ability to reduce failed fill and prevent expensive product contamination.

Conclusion

The future of precision medicine in manufacturing is extremely exciting. With the continuation of this more selective model of manufacturing, it is likely that manufacturing of the product will become increasingly on-site, removing logistics and transport costs and bringing the drug closer to the patient it is intended for.

This could be improved further by use of AI and machine learning, creating a self-learning supply chain that reacted to distribution of product exactly as needed, removing all waste and reducing costs significantly. While this is still a significant way off – the expertise to work with this AI does not exist in a large way yet – it promises not only to create medicines that are better suited to whichever patient they are intended for, but also that are cheaper, faster to supply and with less waste for pharma companies to deal with.

Joshua Neil, Editor

Proventa International

Subscribe

to get our

LATEST NEWS

Related Posts

AI, Data & Technology

The Power of Unsupervised Learning in Healthcare

In healthcare’s dynamic landscape, the pursuit of deeper insights and precision interventions is paramount, where unsupervised learning emerges as a potent tool for revealing hidden data structures.

AI, Data & Technology

Unlocking Intelligence: A Journey through Machine Learning

ML stands as a cornerstone of technological advancement, permeating various facets of our daily lives.

Read More Articles

Synthetic Chemistry’s Potential in Deciphering Antimicrobial Peptides

The saga of antimicrobial peptides unfolds as a testament to scientific ingenuity and therapeutic resilience.

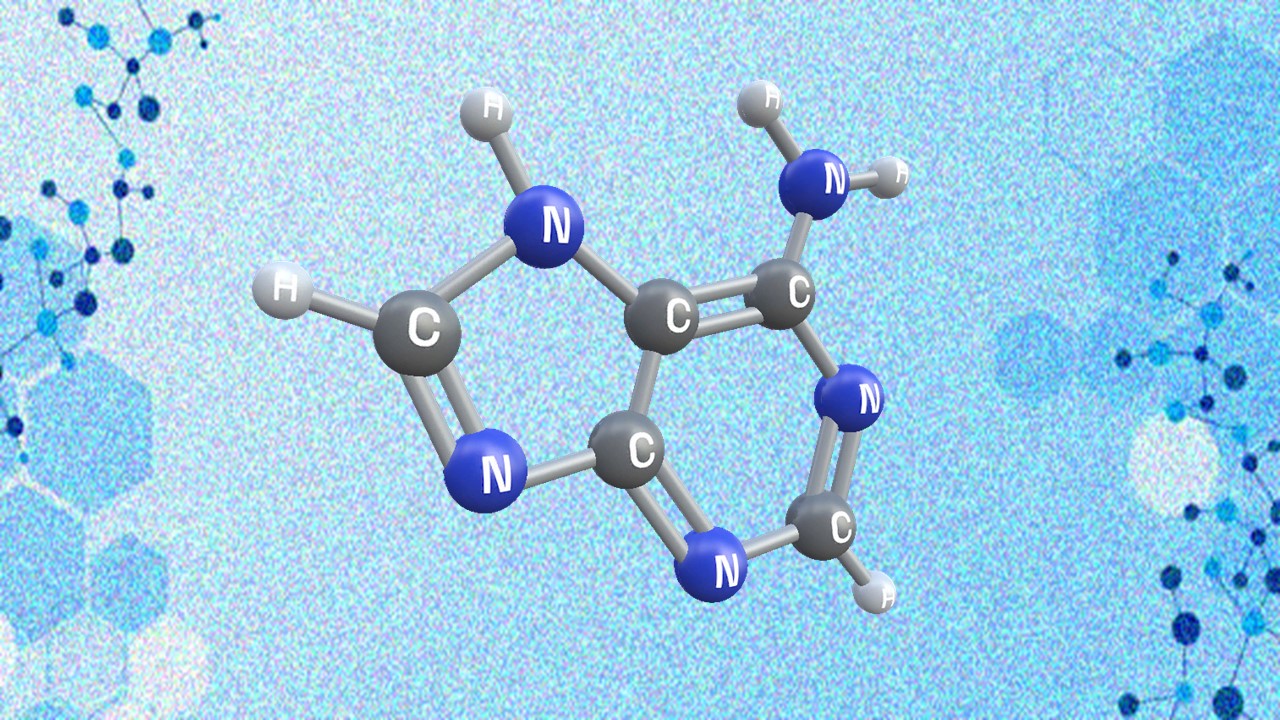

Appreciating the Therapeutic Versatility of the Adenine Scaffold: From Biological Signaling to Disease Treatment

Researchers are utilizing adenine analogs to create potent inhibitors and agonists, targeting vital cellular pathways from cancer to infectious diseases.