The Architecture of Bio-Based Scaffolds

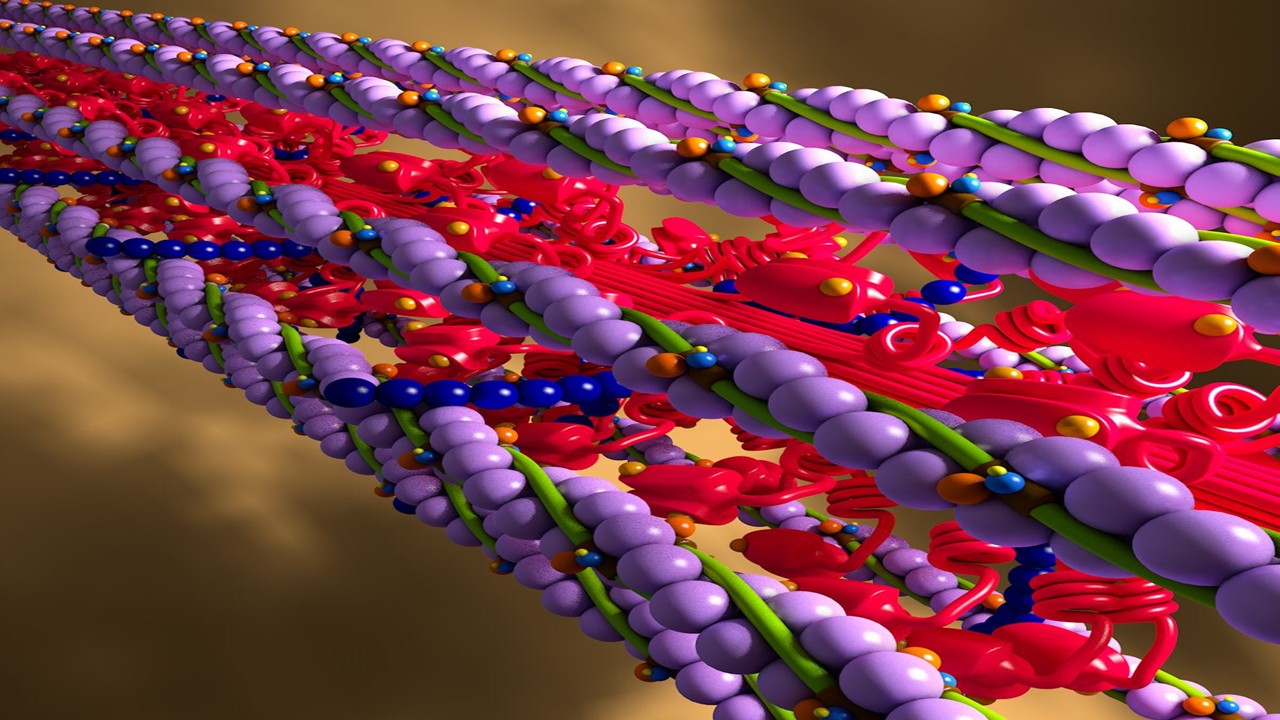

Bio-based scaffolds function as structural templates that facilitate tissue regeneration by providing an extracellular matrix (ECM)-like environment. Unlike synthetic alternatives, which often lack biological recognition sites, natural polymer-based scaffolds—such as those derived from collagen, fibrin, and alginate—support cellular adhesion, proliferation, and differentiation. Their porous architecture is crucial for oxygen diffusion, nutrient transport, and metabolic waste removal, all of which are essential for cell survival and functional tissue development. The biomechanical properties of these scaffolds can be tailored to mimic native tissues, ensuring mechanical integrity and compatibility with host environments.

Advancements in fabrication techniques have enabled precise control over scaffold microstructure and composition. Electrospinning, for example, generates nanofibrous scaffolds that closely resemble native ECM structures, providing a fibrous topology that enhances cell anchorage and migration. Alternatively, freeze-drying creates highly porous, interconnected networks suitable for soft tissue applications, while 3D bioprinting allows for patient-specific scaffold designs with predefined geometries and controlled material deposition. These technologies collectively optimize scaffold architecture, ensuring both structural and functional compatibility with targeted tissues.

Beyond physical design, bio-based scaffolds can be functionalized with bioactive molecules to enhance cellular interactions. Incorporating growth factors such as vascular endothelial growth factor (VEGF) promotes angiogenesis, while bone morphogenetic proteins (BMPs) stimulate osteogenic differentiation. Additionally, surface modifications—such as the grafting of adhesive peptides—can improve integrin-mediated cell attachment. This biomolecular integration ensures that scaffolds do more than passively support tissue growth; they actively participate in regenerative processes, creating a dynamic interface between engineered and native tissues.

Biocompatibility and Degradability: Essential Criteria for Success

Biocompatibility remains a cornerstone of scaffold design, dictating how well the material integrates with host tissues without triggering adverse immune responses. Natural polymers, derived from endogenous biological sources, generally exhibit superior biocompatibility compared to synthetic alternatives. Scaffolds composed of decellularized ECM, for instance, retain native tissue-specific proteins and bioactive cues, allowing for seamless integration into target tissues. Unlike synthetic polymers, which often require surface treatments to enhance cell adhesion, bio-based scaffolds inherently provide cellular recognition sites that facilitate tissue remodeling and repair.

Degradability is equally critical, as an ideal scaffold should provide temporary structural support before gradually being resorbed and replaced by newly formed tissue. The degradation rate must align with the tissue’s healing timeline; too rapid degradation results in mechanical instability, while excessive persistence may lead to chronic inflammation. Enzymatically degradable polymers such as fibrin and hyaluronic acid naturally degrade in response to cellular enzymatic activity, ensuring synchronized scaffold resorption with tissue formation. Meanwhile, composite scaffolds—blending fast- and slow-degrading polymers—allow for tunable degradation kinetics tailored to specific applications.

The degradation byproducts of bio-based scaffolds must also be non-toxic and easily metabolized or excreted by the body. Polysaccharide-based scaffolds, such as chitosan, degrade into bioactive oligosaccharides that possess antimicrobial and anti-inflammatory properties, further promoting wound healing. Similarly, collagen scaffolds degrade into amino acids that can be reused in metabolic pathways. By designing scaffolds with controlled degradation profiles, researchers ensure not only structural support but also a biochemically favorable environment for tissue repair.

Clinical Applications: From Bone Regeneration to Organ Engineering

Bio-based scaffolds have demonstrated remarkable efficacy in diverse clinical applications, ranging from musculoskeletal repair to complex organ regeneration. In bone tissue engineering, scaffolds composed of hydroxyapatite and collagen serve as osteoconductive matrices, guiding the deposition of new bone tissue while providing mechanical stability. These scaffolds promote osteoblast attachment and differentiation, accelerating fracture healing and bone defect repair. Additionally, composite scaffolds combining bioactive ceramics with degradable polymers offer an optimal balance between structural integrity and biological integration, making them viable alternatives to traditional bone grafts.

In soft tissue engineering, scaffolds derived from natural hydrogels—such as hyaluronic acid and gelatin—support the regeneration of skin, cartilage, and vascular tissues. Wound dressings fabricated from chitosan-based scaffolds not only facilitate epithelialization but also exhibit antimicrobial properties, reducing infection risks in chronic wounds. In cartilage regeneration, hydrogel-based scaffolds provide a mechanically compliant matrix that enhances chondrocyte proliferation and extracellular matrix deposition, mitigating the degenerative effects of osteoarthritis. These biomaterial innovations hold promise for replacing damaged soft tissues with functionally equivalent engineered alternatives.

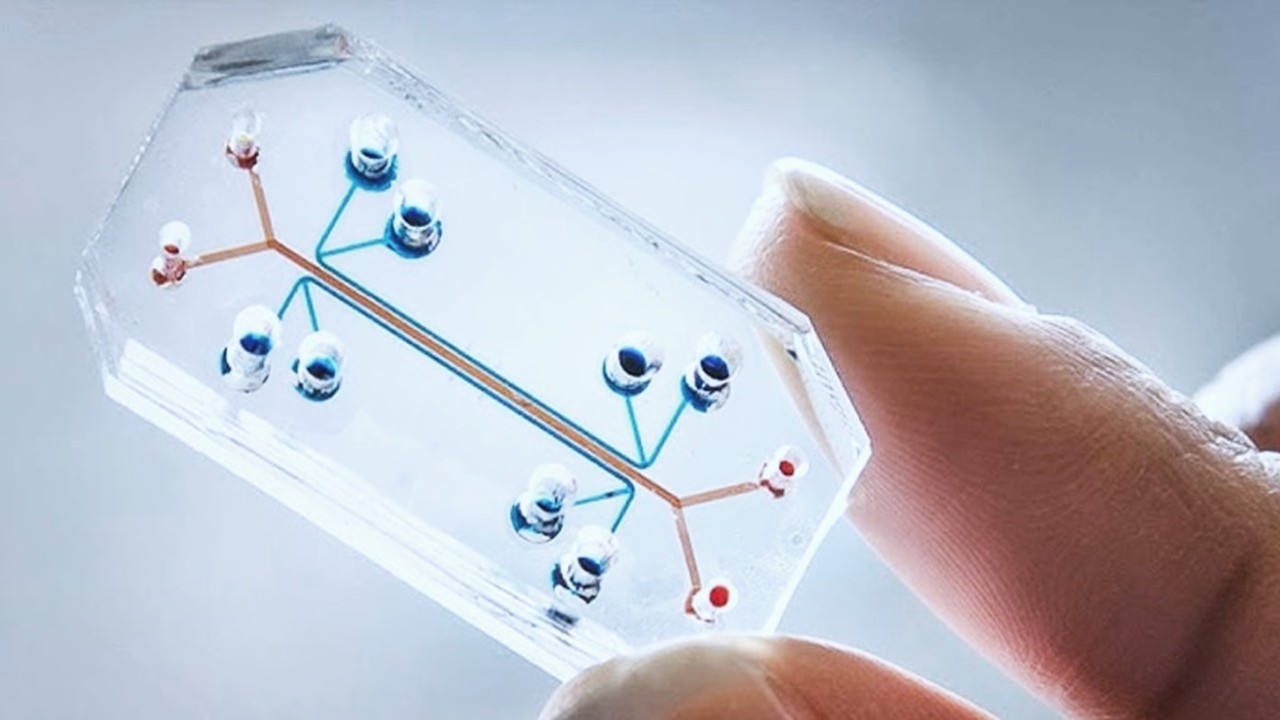

Beyond musculoskeletal and soft tissue repair, bio-based scaffolds play an emerging role in organ engineering. Decellularized tissue scaffolds, which retain the native ECM architecture of organs, serve as templates for whole-organ regeneration. This approach has been successfully applied in kidney, liver, and lung engineering, where the scaffold acts as a guiding framework for stem cell repopulation. With ongoing advances in vascularization techniques, bio-based scaffolds may soon provide functional tissue replacements for patients suffering from organ failure, reducing dependence on organ transplantation.

Sustainability and Green Biomanufacturing in Scaffold Production

The shift toward bio-based scaffolds aligns with sustainability initiatives aimed at reducing the environmental impact of biomedical manufacturing. Traditional scaffold production often involves synthetic polymers derived from petroleum-based sources, leading to long-term environmental persistence and waste accumulation. By contrast, bio-based scaffolds utilize renewable, biodegradable materials that integrate seamlessly into natural biogeochemical cycles. This shift not only improves biocompatibility but also minimizes ecological footprints associated with medical waste disposal.

Green biomanufacturing processes further enhance the sustainability of scaffold production. Microbial fermentation, for example, enables the biosynthesis of polysaccharides such as alginate and bacterial cellulose, providing a scalable and eco-friendly method for biomaterial production. Similarly, recombinant protein expression systems allow for the sustainable production of bioengineered collagen and silk fibroin, eliminating the need for animal-derived sources. These advancements reduce the reliance on non-renewable resources while ensuring consistent scaffold quality for clinical applications.

Additionally, the integration of closed-loop bioprocessing and waste recycling strategies minimizes material waste in scaffold fabrication. Additive manufacturing techniques, such as 3D bioprinting, optimize material utilization by precisely depositing biomaterials layer-by-layer, eliminating excess waste generated in traditional scaffold fabrication. By embracing sustainable material sourcing and manufacturing practices, the biomedical industry can develop regenerative solutions that not only restore human health but also uphold environmental responsibility.

The Future of Bio-Based Scaffolds in Regenerative Medicine

Bio-based scaffolds represent a paradigm shift in regenerative medicine, offering biologically inspired frameworks that support tissue healing and functional restoration. By leveraging natural polymers, advanced fabrication techniques, and bioactive modifications, these scaffolds provide a versatile platform for engineering a wide range of tissues, from bone and cartilage to vascular and organ structures. Their inherent biocompatibility, degradability, and ability to interact with host cells set them apart from synthetic alternatives, making them ideal candidates for clinical translation.

While challenges remain—such as optimizing mechanical properties, ensuring reproducibility, and scaling up production—ongoing research continues to push the boundaries of scaffold technology. The convergence of biofabrication, stem cell therapy, and precision medicine promises to further refine scaffold-based regenerative therapies, moving closer to fully functional, patient-specific tissue replacements. Additionally, the incorporation of sustainability principles into scaffold manufacturing ensures that regenerative medicine advances in harmony with environmental conservation.

As the field evolves, bio-based scaffolds will continue to drive innovations that redefine how we approach tissue regeneration. Whether through personalized implants, 3D-printed organs, or biodegradable wound dressings, these biomaterials are paving the way for a future where damaged tissues can be seamlessly repaired, restoring both function and quality of life for patients worldwide.

Engr. Dex Marco Tiu Guibelondo, B.Sc. Pharm, R.Ph., B.Sc. CpE

Subscribe

to get our

LATEST NEWS

Related Posts

Chemistry, Manufacturing & Controls

Harvesting the Heat: Reclaiming Industrial Energy Losses through Next-Generation Waste Heat Recovery Technologies

Waste heat recovery is now essential—technically sound, economically viable, and environmentally critical.

Chemistry, Manufacturing & Controls

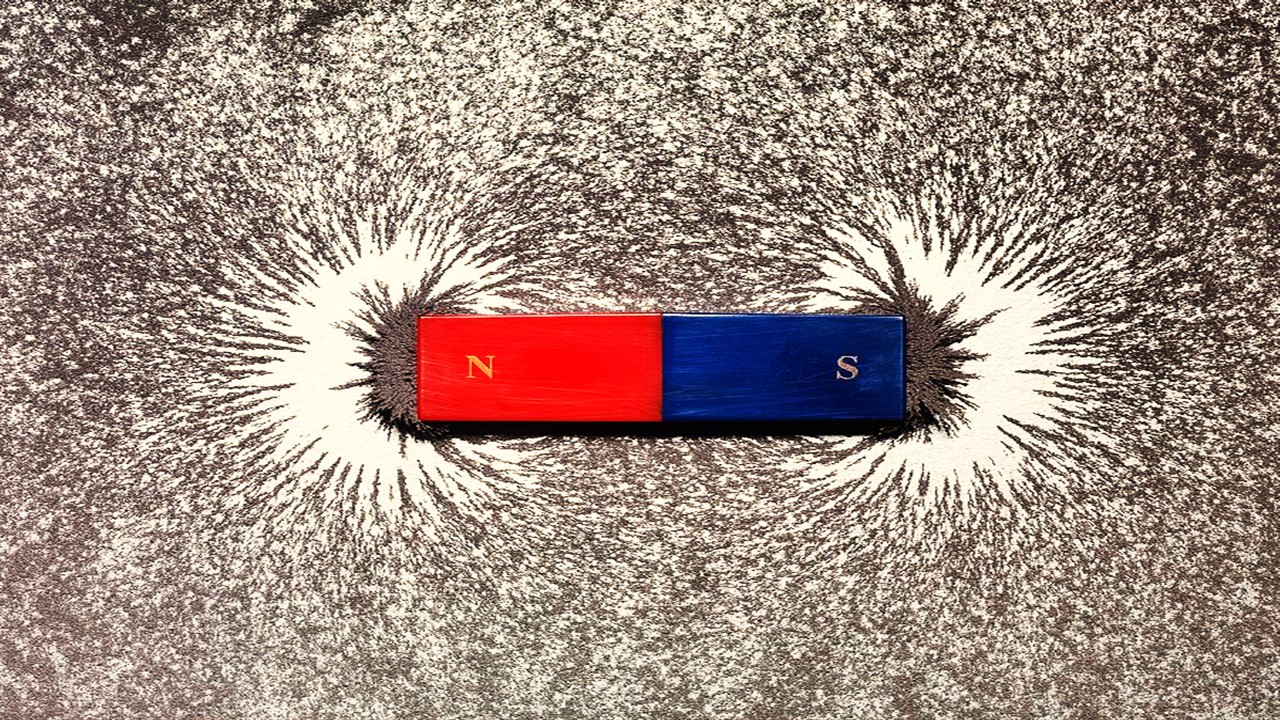

Magnetic Nanoengineering: Overcoming Biological Variability and Enhancing Therapeutic Precision

The future of nanomedicine lies in harmonizing precision, accessibility, and ecological responsibility, ushering in an era where therapies are tailored to individual biological landscapes.

Read More Articles

Myosin’s Molecular Toggle: How Dimerization of the Globular Tail Domain Controls the Motor Function of Myo5a

Myo5a exists in either an inhibited, triangulated rest or an extended, motile activation, each conformation dictated by the interplay between the GTD and its surroundings.