Within the scientific community, the quest for equivalence among drug formulations from various manufacturers has garnered significant attention. This pursuit hinges on unraveling the complexities of bioavailability, a pivotal factor influencing the clinical efficacy of pharmaceuticals.

Unraveling Bioavailability Dynamics

Bioavailability, a cornerstone concept in pharmacology, refers to the fraction of an administered dose of a drug that reaches systemic circulation in an unchanged form, thereby exerting its pharmacological effect. It encompasses both the rate and extent of drug absorption, reflecting the dynamic interplay between the drug formulation and the physiological processes governing absorption.

Formulation and manufacturing processes play pivotal roles in shaping the bioavailability of pharmaceuticals. Formulation pertains to the composition and design of the drug product, encompassing the selection of excipients, particle size, dosage form, and formulation techniques. Manufacturing processes involve the actual production steps, such as blending, granulation, compression, and coating, which can influence the physical characteristics and performance of the final product.

Even subtle variations in formulation or manufacturing parameters can yield distinct bioavailability profiles. For example, changes in particle size distribution can alter dissolution kinetics, affecting the rate at which the drug is released from the dosage form and subsequently absorbed. Likewise, variations in excipient composition, such as the type and concentration of binders, disintegrants, or lubricants, can modulate drug dissolution, solubility, and permeability in the gastrointestinal tract.

These nuances in bioavailability can have profound implications for therapeutic outcomes. Variability in drug absorption may lead to fluctuations in systemic drug concentrations, potentially compromising efficacy or safety. Inadequate absorption may result in suboptimal therapeutic effects, while excessive absorption could elevate the risk of adverse reactions or toxicity.

Moreover, bioavailability discrepancies among generic and brand-name formulations or between different batches of the same product underscore the importance of rigorous quality control measures and bioequivalence testing. Regulatory agencies, such as the FDA, mandate stringent requirements to ensure the comparability of generic drug products with their reference counterparts, emphasizing the need for comprehensive understanding and control of formulation and manufacturing variables.

Dissolution Testing: A Window into Equivalence

Dissolution testing is a fundamental component of pharmaceutical analysis prescribed by the United States Pharmacopeia (USP), one that holds immense significance in the evaluation of drug bioequivalence. This method provides valuable insights into the dissolution behavior of drug formulations, offering a window into their performance characteristics and potential impact on bioavailability.

At its core, dissolution testing involves measuring the rate and extent of drug release from a dosage form, typically tablets or capsules, under standardized conditions that simulate physiological environments. By subjecting the formulation to a predetermined dissolution medium with controlled agitation and temperature, the test assesses how effectively the drug dissolves and becomes available for absorption.

One of the primary objectives of dissolution testing is to uncover formulation attributes that can influence drug absorption kinetics and, consequently, bioequivalence. For instance, variations in particle size distribution, a critical parameter in drug formulation, can profoundly affect dissolution rates. Smaller particle sizes generally facilitate faster dissolution, leading to enhanced bioavailability, whereas larger particles may exhibit slower dissolution kinetics, potentially impeding absorption.

Additionally, dissolution testing offers insights into the impact of excipients, such as lubricants and coating materials, on drug release. Excessive amounts of lubricants, such as magnesium stearate, can hinder dissolution by forming hydrophobic barriers that impede drug dissolution. Similarly, inadequate coating or the use of suboptimal coating materials may affect drug release patterns, altering absorption dynamics.

By scrutinizing dissolution behavior, dissolution testing enables formulation scientists and regulatory agencies to discern bioinequivalence between ostensibly equivalent drug products. Discrepancies in dissolution profiles may signal underlying differences in formulation or manufacturing processes, highlighting the need for further investigation and potential regulatory action.

FDA Classifications: Establishing Equivalency Standards

The Food and Drug Administration (FDA) employs a meticulous classification system to delineate the interchangeability and therapeutic effectiveness of drug products, categorizing them into pharmaceutical equivalents, pharmaceutical alternatives, and bioequivalent drug products. Each category is defined by specific criteria that encapsulate essential aspects of drug formulation, composition, and pharmacokinetic behavior.

Pharmaceutical equivalents represent a category of drug products characterized by identical amounts of active drug ingredients, typically the same salt or ester of the therapeutic moiety. While pharmaceutical equivalents share identical dosage forms, they may vary in inactive ingredients. Despite this disparity, pharmaceutical equivalents must meet stringent standards of identity, strength, quality, and purity, ensuring comparable pharmacological effects and clinical outcomes.

In contrast, pharmaceutical alternatives encompass drug products containing the same therapeutic moiety or its precursor, albeit in varying amounts, dosage forms, or chemical compositions. Unlike pharmaceutical equivalents, pharmaceutical alternatives may deviate from the identical compendial standards but must individually meet their own set of specifications regarding identity, strength, quality, and purity. This category allows for flexibility in drug formulation and presentation while ensuring therapeutic efficacy and safety.

Bioequivalent drug products constitute a distinct category distinguished by their comparable rates and extents of absorption under similar experimental conditions. These products, whether pharmaceutical equivalents or alternatives, demonstrate no significant differences in absorption kinetics when administered at equivalent doses. While absolute bioequivalence is rarely achieved due to inherent variability in drug formulation and physiological responses, bioequivalent drug products exhibit sufficiently similar pharmacokinetic profiles to be considered therapeutically equivalent.

By categorizing drug products into pharmaceutical equivalents, pharmaceutical alternatives, and bioequivalent drug products, the FDA establishes clear guidelines for assessing the interchangeability and therapeutic effectiveness of pharmaceutical formulations. This classification framework underscores the importance of rigorous quality standards and pharmacokinetic comparability in ensuring the safety, efficacy, and therapeutic equivalence of drug products available to patients.

Challenges in Achieving Bioequivalence

Discrepancies in bioavailability have been documented among diverse formulations and batches of pharmaceutical products. These variations persist despite regulatory oversight and efforts to standardize manufacturing processes. Achieving absolute bioequivalence, wherein different formulations or batches yield identical pharmacokinetic profiles, remains an elusive goal due to the inherent complexities and variability inherent in formulation and manufacturing practices.

The intricate interplay of formulation components, manufacturing techniques, and environmental factors can significantly impact the bioavailability of drugs. Minor alterations in formulation parameters, such as particle size, excipient composition, or coating materials, may exert profound effects on drug dissolution, absorption kinetics, and ultimately, therapeutic efficacy. Additionally, variations in manufacturing processes, such as mixing, granulation, and compression methods, can introduce subtle differences in product characteristics that influence drug release and systemic exposure.

Despite stringent regulatory standards and quality control measures, inherent variability in formulation and manufacturing processes poses ongoing challenges to ensuring consistent bioavailability across different drug products. Even minor deviations in manufacturing conditions or raw material quality can manifest as differences in dissolution behavior and pharmacokinetic profiles, leading to disparities in therapeutic outcomes.

Furthermore, the complexity of biological systems and individual patient variability further complicates efforts to achieve uniform bioequivalence. Factors such as gastrointestinal physiology, metabolic differences, and genetic polymorphisms can influence drug absorption and disposition, contributing to variability in drug response among patients.

In light of these challenges, regulatory agencies and pharmaceutical manufacturers continue to refine and optimize formulation and manufacturing processes to enhance product consistency and bioequivalence. By employing advanced analytical techniques, process control strategies, and quality assurance measures, stakeholders endeavor to minimize variability and ensure the reliability and therapeutic equivalence of pharmaceutical products. However, the inherent complexity of drug formulation and biological systems necessitates ongoing vigilance and innovation to address disparities in bioavailability and optimize therapeutic outcomes for patients.

Illuminating Equivalence with Crossover Trials

Crossover design studies represent a cornerstone in the evaluation of bioavailability differences among various drug formulations. These trials are meticulously designed to compare the pharmacokinetic profiles of different products within the same group of subjects, offering valuable insights into their relative performance in terms of drug absorption and systemic exposure.

Central to the crossover design is its ability to minimize inter-subject variability by employing a within-subject comparison approach. In these studies, each participant serves as their own control, receiving different formulations of the same drug in a randomized sequence. By administering both formulations to each subject, the influence of individual variability in drug absorption and metabolism is effectively mitigated, thereby enhancing the reliability and interpretability of the study results.

During the course of the crossover study, blood or plasma samples are collected at predetermined time points following drug administration. These samples are then subjected to rigorous analytical analysis to quantify the concentration of the active drug and its metabolites over time. By comparing key pharmacokinetic parameters such as peak plasma concentration (Cmax), time to peak concentration (Tmax), and area under the concentration-time curve (AUC), researchers can assess the comparative bioavailability of the test formulations.

Importantly, crossover design studies incorporate a washout period between successive administrations of different formulations to minimize carryover effects and ensure data integrity. This interval allows for the elimination of any residual drug from the previous treatment period, preventing its confounding influence on the pharmacokinetic analysis of subsequent formulations.

Once data collection is complete, statistical analysis is employed to compare the pharmacokinetic parameters of interest between the different formulations. By applying robust statistical methods, researchers can ascertain whether any observed differences in drug absorption are statistically significant and, by extension, clinically relevant.

Patient-Centric Considerations

Although drugs may be deemed therapeutically equivalent based on standardized criteria, the intricacies of patient-specific factors underscore the necessity for meticulous consideration in product selection and interchangeability. While two drug formulations may exhibit comparable efficacy and safety profiles in controlled clinical settings, individual patient characteristics and preferences can significantly influence treatment outcomes and adherence.

One critical consideration in product selection is the potential for hypersensitivity reactions to specific formulation components. In some cases, patients may exhibit allergic or intolerant responses to inert ingredients present in certain drug formulations, such as dyes, preservatives, or excipients. Even though the active pharmaceutical ingredient remains consistent across different products, variations in formulation components can elicit disparate immune responses in susceptible individuals. Therefore, healthcare providers must exercise caution when prescribing or dispensing medications, taking into account each patient’s known allergies and sensitivities to specific ingredients.

Moreover, adherence concerns further underscore the importance of personalized pharmacotherapeutic decisions. Patients may develop familiarity and confidence with a particular drug formulation, adapting to its appearance, taste, or packaging over the course of their treatment regimen. Introducing changes in product formulation, such as switching between brand-name and generic versions or alternative dosage forms, can disrupt established medication routines and potentially compromise treatment adherence. Patients may experience confusion, anxiety, or reluctance to comply with therapy if confronted with unfamiliar or dissimilar drug products, leading to suboptimal therapeutic outcomes and increased healthcare costs associated with medication non-adherence.

Therefore, healthcare professionals must engage in thoughtful patient counseling and education regarding potential changes in drug formulations, emphasizing the rationale behind such decisions and addressing any concerns or misconceptions patients may harbor. Shared decision-making processes that prioritize patient preferences and experiences can foster collaborative therapeutic relationships and enhance treatment adherence. By considering both clinical efficacy and patient-centered factors in product selection and interchangeability, healthcare providers can optimize medication management strategies and promote favorable treatment outcomes for individual patients.

Charting Future Frontiers

Sustained collaborations among regulatory bodies, manufacturers, and healthcare providers are essential for advancing our understanding of drug equivalence. This ongoing partnership fosters the exchange of scientific insights, regulatory guidance, and clinical expertise to optimize patient outcomes and refine pharmaceutical practices. Regulatory agencies establish rigorous standards for drug approval and oversight, incentivizing manufacturers to adhere to quality control measures. Meanwhile, manufacturers conduct research to optimize formulations and manufacturing processes. Healthcare providers offer frontline insights, guiding regulatory decisions and pharmaceutical development efforts. Through these collaborations, the scientific community aims to overcome challenges and improve drug equivalence, benefiting patients globally.

Engr. Dex Marco Tiu Guibelondo, B.Sc. Pharm, R.Ph., B.Sc. CpE

Editor-in-Chief, PharmaFEATURES

Subscribe

to get our

LATEST NEWS

Related Posts

Medicinal Chemistry & Pharmacology

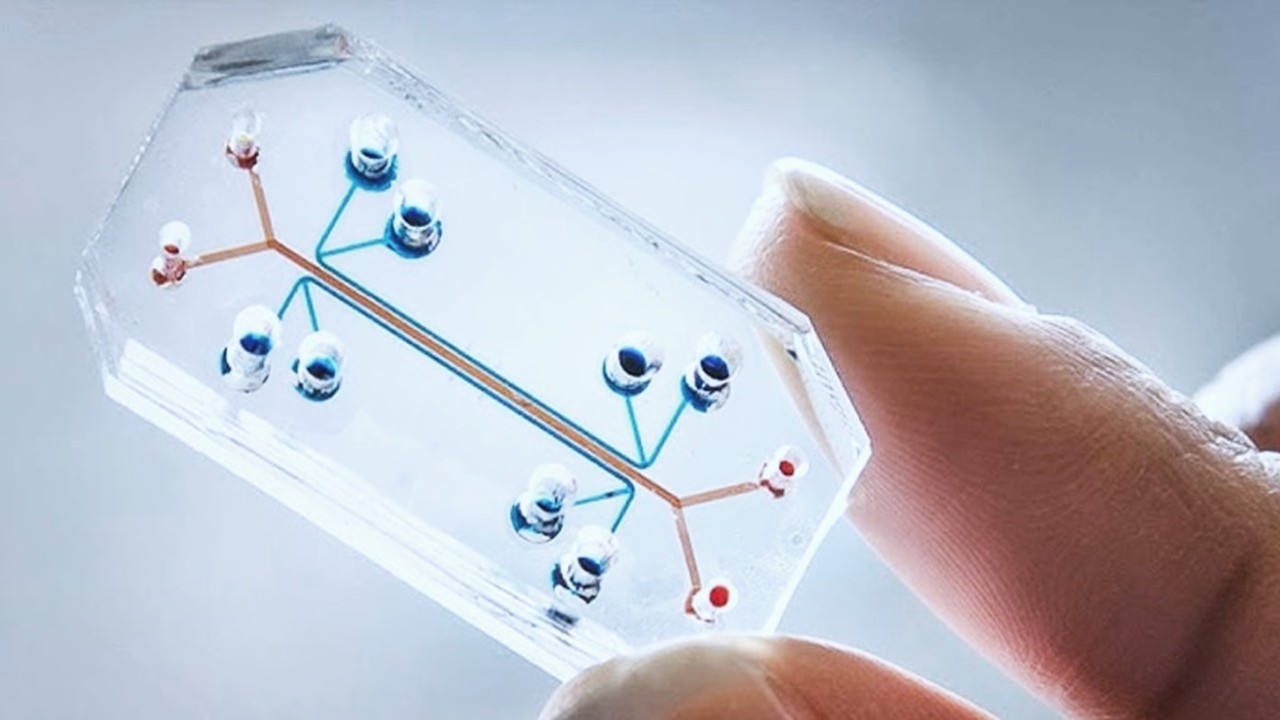

Invisible Couriers: How Lab-on-Chip Technologies Are Rewriting the Future of Disease Diagnosis

The shift from benchtop Western blots to on-chip, real-time protein detection represents more than just technical progress—it is a shift in epistemology.

Medicinal Chemistry & Pharmacology

Designing Better Sugar Stoppers: Engineering Selective α-Glucosidase Inhibitors via Fragment-Based Dynamic Chemistry

One of the most pressing challenges in anti-diabetic therapy is reducing the unpleasant and often debilitating gastrointestinal side effects that accompany α-amylase inhibition.

Medicinal Chemistry & Pharmacology

Into the Genomic Unknown: The Hunt for Drug Targets in the Human Proteome’s Blind Spots

The proteomic darkness is not empty. It is rich with uncharacterized function, latent therapeutic potential, and untapped biological narratives.

Medicinal Chemistry & Pharmacology

Aerogel Pharmaceutics Reimagined: How Chitosan-Based Aerogels and Hybrid Computational Models Are Reshaping Nasal Drug Delivery Systems

Simulating with precision and formulating with insight, the future of pharmacology becomes not just predictive but programmable, one cell at a time.

Read More Articles

Myosin’s Molecular Toggle: How Dimerization of the Globular Tail Domain Controls the Motor Function of Myo5a

Myo5a exists in either an inhibited, triangulated rest or an extended, motile activation, each conformation dictated by the interplay between the GTD and its surroundings.