Biosimilars are biologic medications crafted to mirror existing, approved biologic drugs, which themselves are complex medications derived from living organisms. While biosimilars closely resemble their original reference biologics in structure and function, they are produced by separate manufacturers after the original drug’s patent expires. This shared foundation with biologics explains the similar therapeutic effects biosimilars offer in treating diseases such as cancer, autoimmune disorders, and chronic conditions like diabetes.

One defining characteristic of biosimilars is their production through biologically active materials, such as living cells and microorganisms, making their manufacturing notably complex. These “follow-on” biologics are not exact replicas of the original biologic due to inherent variances in biological sources and manufacturing processes. Nonetheless, regulatory bodies have established rigorous standards to confirm that biosimilars provide the same safety and efficacy profile as their reference biologics. This consistency assures patients and healthcare providers of comparable therapeutic outcomes.

Approval Standards: Ensuring Safety and Efficacy

The pathway to biosimilar approval is distinct from that of traditional generics. Because of the biological sources and complex production techniques involved, biosimilars undergo extensive testing to establish their similarity to the reference biologic without necessitating identical clinical trials. This process includes analytical studies to assess structural similarity, animal studies to understand potential toxicity, and clinical evaluations on pharmacokinetics, pharmacodynamics, and immunogenicity.

Internationally, organizations like the World Health Organization (WHO) have set guidelines for biosimilar evaluation, while region-specific regulatory bodies such as the European Medicines Agency (EMA) and the United States Food and Drug Administration (FDA) conduct independent reviews. The FDA, for example, evaluates biosimilars based on comparative evidence that includes structural, functional, and clinical safety data. This regulatory oversight assures patients of equivalent therapeutic benefits, minimizing risks of adverse effects that might arise from slight molecular differences.

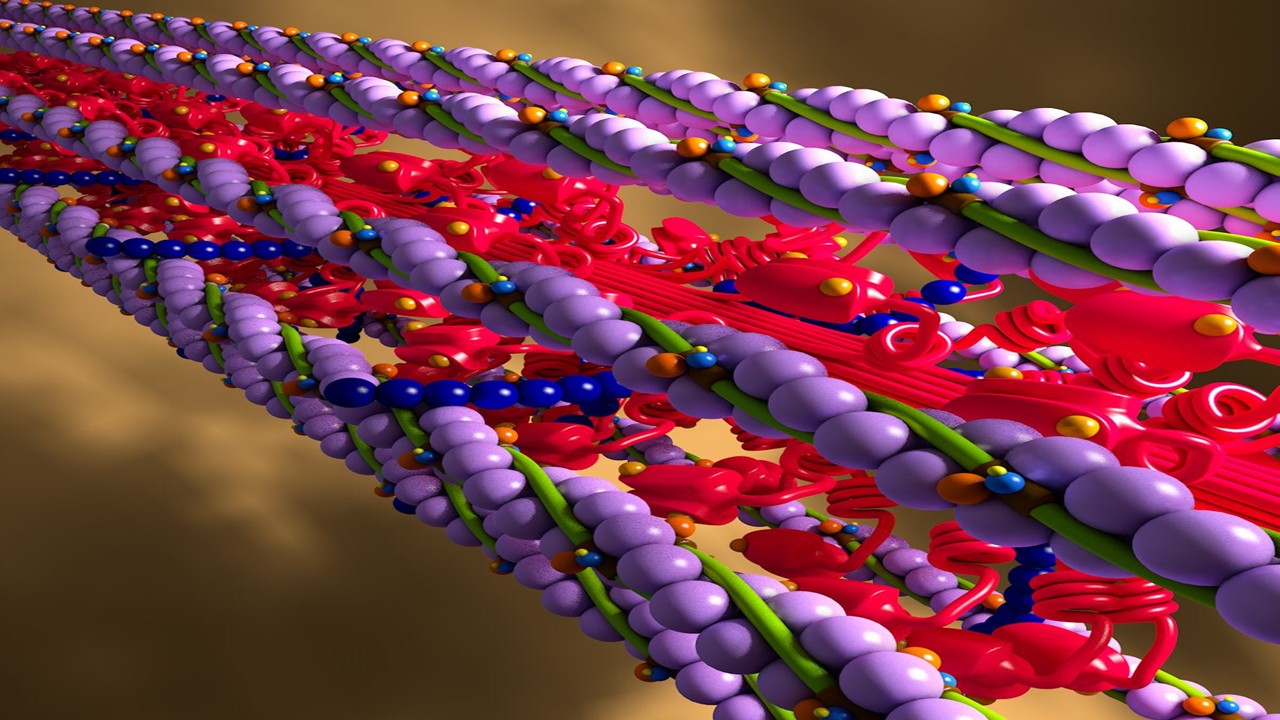

The Complexity Behind Biologic Manufacturing

Biologics differ significantly from small-molecule drugs. Where small-molecule drugs can be synthesized with precise chemical formulas, biologics are developed through recombinant DNA technology in living cells. These cells are engineered to produce therapeutic proteins, which are then purified and formulated into medication. Variations in cell lines, purification processes, and formulations all contribute to the unique attributes of each biologic batch. This complexity presents a challenge for biosimilar manufacturers, who must meet stringent quality control measures to align their products with the original reference biologic.

For biosimilars, minor differences in inactive components are permissible, provided they do not alter the clinical efficacy or safety profile. To that end, biosimilar manufacturers employ advanced analytical methods to maintain consistency across production batches. By ensuring that even slight modifications do not affect clinical outcomes, biosimilars can confidently match the therapeutic impact of their biologic counterparts, providing an affordable alternative without compromising quality.

Regulation and Pharmacovigilance: Monitoring Patient Safety

The introduction of biosimilars has been accompanied by enhanced pharmacovigilance measures. The EMA and FDA, for example, require biosimilar manufacturers to submit a risk management plan outlining post-approval monitoring protocols. Regular safety updates, along with ongoing clinical evaluations, help in identifying any emergent risks or adverse reactions associated with biosimilars.

In the United States, the FDA has classified certain biosimilars as “interchangeable,” meaning they can be substituted for their reference biologic without the need for prescriber approval, similar to generic substitutions. This interchangeability status, however, depends on additional data demonstrating that switching between the biosimilar and the reference product does not compromise efficacy or safety. The FDA’s vigilance ensures that biosimilars remain a safe, effective, and accessible option for patients needing biologic treatment.

Expanding Treatment Access Through Cost Efficiency

One of the most compelling reasons for the expansion of biosimilars is their potential to lower healthcare costs. While biosimilars are typically less expensive than their original biologics, this reduced cost does not reflect diminished quality or therapeutic impact. Instead, biosimilars benefit from the established data supporting their reference products, streamlining the approval process and reducing the need for redundant clinical trials.

As more biosimilars enter the market, competition grows, offering patients affordable treatment options without sacrificing efficacy. For many individuals, this can translate to broader insurance coverage and reduced out-of-pocket expenses. Biosimilars thus represent a vital step toward more equitable access to biologic treatments, especially for those managing chronic or severe conditions.

Applications of Biosimilars in Chronic and Life-Threatening Diseases

Biosimilars have broadened the scope of accessible treatment for numerous conditions. Patients with diseases like rheumatoid arthritis, inflammatory bowel disease, and certain cancers now have more treatment options due to biosimilar availability. Insulin, a life-sustaining therapy for diabetes, is also seeing expansion through biosimilar options, which offer an alternative to traditionally expensive branded insulin products.

For patients with chronic skin disorders like psoriasis or debilitating conditions like multiple sclerosis, biosimilars allow for continued treatment at potentially lower costs, increasing medication adherence and overall health outcomes. The FDA and other regulatory agencies ensure that each biosimilar matches the reference biologic’s safety profile, assuring both physicians and patients of its reliability.

Addressing Questions on Biosimilars and Generics: Similarities and Differences

Despite some similarities, biosimilars differ fundamentally from generic drugs. While generics replicate small-molecule drugs with chemically identical structures, biosimilars cannot identically match their biologic reference products due to the living sources from which they are derived. Consequently, the FDA and EMA have developed separate approval pathways for biosimilars and generics, acknowledging the distinct manufacturing and testing complexities inherent to each.

Both biosimilars and generics undergo rigorous quality checks, but biosimilars face additional scrutiny due to the potential for immunogenic reactions. These approvals hinge on extensive evidence that supports comparable pharmacodynamics, ensuring biosimilars meet the same therapeutic standards as their reference biologics. This stringent oversight instills confidence in biosimilars’ safety and efficacy, bridging an important gap between accessibility and quality in biologic treatments.

Future Directions: Evolving Guidelines and Patient-Centered Care

As biosimilars become more prevalent, regulatory agencies are continuously refining their guidelines to accommodate advancements in biosimilar technology and clinical applications. For instance, upcoming biosimilar insulins offer a promising option for patients with diabetes, providing more alternatives in disease management. By standardizing approval criteria and enhancing patient education on biosimilars, healthcare systems can empower individuals to make informed treatment decisions.

Looking ahead, the biosimilar industry is poised to reshape healthcare by providing high-quality, cost-effective biologic treatments to a broader patient population. With rigorous clinical and pharmacovigilance standards in place, biosimilars embody a milestone in modern medicine, affirming that affordable innovation can coexist with uncompromised quality and patient safety.

Reference: https://www.fda.gov/drugs/biosimilars/biosimilars-basics-patients

Engr. Dex Marco Tiu Guibelondo, B.Sc. Pharm, R.Ph., B.Sc. CpE

Editor-in-Chief, PharmaFEATURES

Register your interest [here] at Proventa International’s Clinical Operations and Clinical Trials Supply Chain Strategy Meeting this 14th of November 2024 at Le Meridien Boston Cambridge, Massachusetts, USA to engage with thought leaders and like-minded peers on the latest developments in the clinical space and regulatory affairs.

Subscribe

to get our

LATEST NEWS

Related Posts

Biomanufacturing

Biotechnology’s Transformative Impact on Sustainable Development

Rooted in the transition from fossil fuels to renewable resources, the integrated bioeconomy promises a sustainable future.

Biomanufacturing

Matexcel’s Natural Extract Peptides: A Commitment to Quality and Innovation

Matexcel has recently introduced a novel series of natural extract peptide products designed for applications in food supplementation or cosmetic research.

Read More Articles

Myosin’s Molecular Toggle: How Dimerization of the Globular Tail Domain Controls the Motor Function of Myo5a

Myo5a exists in either an inhibited, triangulated rest or an extended, motile activation, each conformation dictated by the interplay between the GTD and its surroundings.