Catalysts are indispensable in modern chemistry, expediting reactions by lowering activation energies and enhancing selectivity. Their role is pivotal in developing energy-efficient processes, particularly in sectors like petrochemical processing and pharmaceutical manufacturing. Recent advancements have significantly improved catalytic efficiency, selectivity, and sustainability, marking a transformative era in chemical manufacturing.

Catalysts: The Molecular Architects of Chemical Transformation

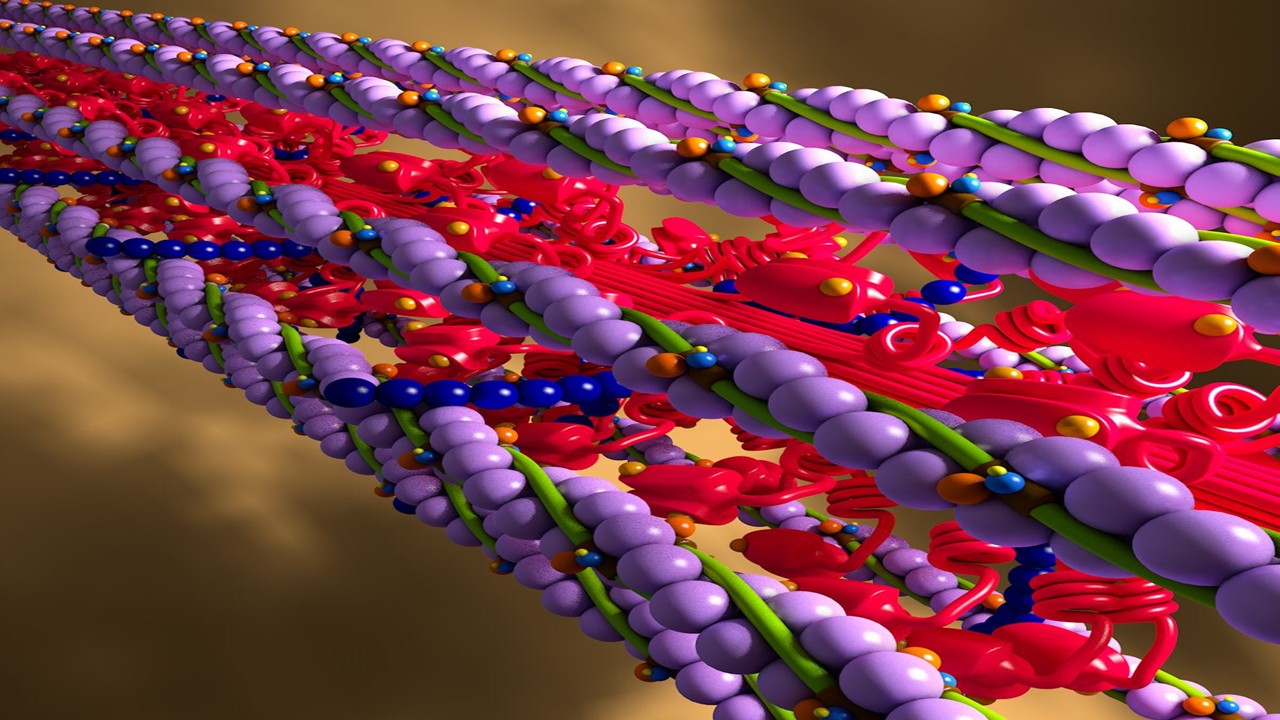

Catalysts are substances that accelerate the rate of a chemical reaction without being consumed in the process. At the molecular level, catalysts function by providing an alternative reaction pathway with a lower activation energy, the minimum energy required for reactants to transform into products. This alternative pathway often involves intermediate steps where the catalyst interacts with the reactants to form transient complexes, stabilizing high-energy transition states that would otherwise be difficult to achieve. By lowering the activation energy, catalysts increase the proportion of reactant molecules that can overcome this energy barrier, thereby enhancing the reaction rate.

The effectiveness of a catalyst is deeply rooted in its molecular structure and surface properties. For instance, in heterogeneous catalysis, where the catalyst is in a different phase than the reactants, the active sites on the catalyst’s surface play a crucial role. These sites facilitate adsorption of reactants, weakening specific bonds and orienting the molecules in a manner that promotes reaction. In homogeneous catalysis, where the catalyst shares the same phase as the reactants, molecular-level interactions involve precise electronic and geometric alignments that enable the catalyst to donate or accept electrons during the reaction. Transition metal catalysts, for example, often employ their variable oxidation states and coordination abilities to stabilize reaction intermediates.

The specificity and efficiency of a catalyst depend on its ability to selectively interact with particular reactants while minimizing side reactions. Enzymes, which are biological catalysts, exemplify this principle through their highly specialized active sites that recognize specific substrates and facilitate reactions under mild conditions. On the other hand, industrial catalysts like zeolites or platinum-based systems are designed to maximize activity and selectivity under high temperatures and pressures. Understanding catalysts at a chemical level not only illuminates their role in natural and industrial processes but also drives innovations in areas like green chemistry, energy production, and pharmaceutical development.

Advancements in Nanocatalysis

Nanocatalysis involves catalysts at the nanometer scale, offering unique properties due to their high surface area-to-volume ratios and quantum effects. These characteristics enable more efficient interactions with reactants, leading to enhanced reaction rates and selectivity. Recent developments have focused on designing nanostructured catalysts with controlled morphologies to optimize performance.

For instance, dendritic fibrous nanosilica has been engineered to maximize surface interactions, improving catalytic efficiency in various reactions. By adjusting the spacing between nanostructures, researchers have tailored these catalysts for specific applications, such as carbon dioxide capture and conversion. This approach not only enhances efficiency but also contributes to sustainability by facilitating the transformation of greenhouse gases into useful chemicals.

Additionally, the integration of metal nanoparticles with nanostructured supports has led to catalysts that exhibit exceptional activity and stability. These hybrid nanocatalysts are being explored for applications in renewable energy, including fuel cells and hydrogen production, where efficient and durable catalysts are essential.

Emergence of Single-Atom Catalysts

Single-atom catalysts (SACs) represent a frontier in catalysis, where individual metal atoms are dispersed on a support material. This maximizes atomic efficiency and provides unique catalytic properties. SACs have demonstrated remarkable performance in reactions like the electrochemical reduction of carbon dioxide, offering pathways to convert CO₂ into valuable fuels and chemicals.

The precision placement of single atoms allows for the fine-tuning of catalytic sites, leading to enhanced selectivity and activity. For example, single-atom nickel catalysts have shown high efficiency in hydrogenation reactions, which are crucial in the production of clean fuels. The development of SACs is poised to revolutionize processes that require high catalytic performance with minimal material usage.

However, challenges remain in stabilizing these single atoms under reaction conditions and preventing aggregation into larger particles. Ongoing research is focused on developing robust support materials and synthesis methods to maintain the dispersion and activity of SACs during catalytic processes.

Integration of Machine Learning in Catalyst Design

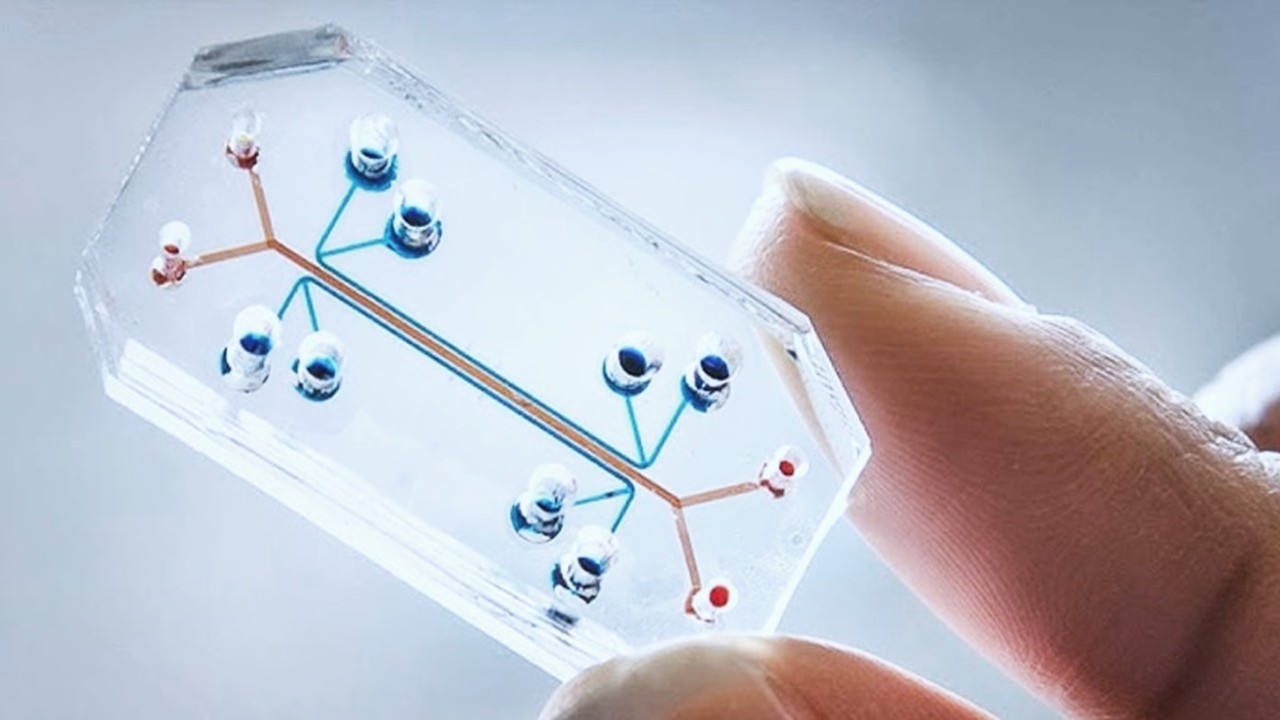

The incorporation of machine learning (ML) techniques into catalyst development has accelerated the discovery and optimization of catalysts for energy-efficient reactions. ML algorithms can predict the performance of potential catalysts by analyzing vast datasets, thereby reducing the reliance on time-consuming and costly experimental trials.

Frameworks like Catlas utilize graph-based machine learning models to explore extensive material design spaces efficiently. By automating the generation of adsorbate-surface configurations and predicting adsorption energies, these tools identify promising catalyst candidates for specific reactions, such as the direct conversion of syngas to multi-carbon oxygenates. This approach streamlines the screening process, enabling the rapid identification of materials with optimal catalytic properties.

Moreover, ML models have been employed to understand the relationship between catalyst structure and activity, guiding the rational design of new catalysts. By learning from existing data, these models can suggest modifications to catalyst compositions and structures that may enhance performance, thereby expediting the development of next-generation catalysts for sustainable chemical processes.

Advances in Photocatalysis for Sustainable Energy

Photocatalysis, which leverages light to drive chemical reactions, has gained prominence in sustainable energy applications. Recent research has focused on developing photocatalysts capable of utilizing solar energy to convert carbon dioxide into fuels like methanol, offering a renewable pathway for fuel production.

For example, NiZn intermetallic catalysts have demonstrated high efficiency in sunlight-driven CO₂ hydrogenation to methanol under atmospheric pressure. The NiZn-ZnO interface in these catalysts stabilizes key intermediates, facilitating the conversion process with remarkable selectivity towards methanol. Such innovations highlight the potential of photocatalysis in creating sustainable and energy-efficient chemical processes.

Additionally, the development of plasmonic photocatalysts, which utilize the plasmon resonance effect to enhance light absorption, has opened new avenues for efficient solar energy utilization. These materials can harvest a broader spectrum of sunlight, increasing the efficiency of photocatalytic reactions and contributing to the advancement of solar fuel production technologies.

Heterogeneous Catalysis in Industrial Applications

Heterogeneous catalysts, which exist in a different phase than the reactants, are extensively used in industrial processes due to their ease of separation and recyclability. Recent studies have emphasized the impact of support materials on the performance of these catalysts, particularly in green synthesis and sustainable processing.

The choice of support material can significantly influence the activity, selectivity, and stability of heterogeneous catalysts. Materials with ideal porosity, surface area, and chemical properties can enhance catalyst performance by providing optimal environments for reactions. For instance, supports like dendritic fibrous nanosilica offer high surface areas and tunable pore structures, facilitating efficient catalytic processes.

Furthermore, the development of eco-friendly support materials aligns with the principles of green chemistry, reducing the environmental impact of catalytic processes. By utilizing sustainable materials and methods in catalyst design, industries can move towards more environmentally benign manufacturing practices.

Sustainable Practices in Catalyst Development

The push towards sustainability has led to the development of green catalysts that adhere to the principles of sustainable chemistry. These catalysts aim to minimize environmental impact by reducing hazardous reagents and waste, and by operating under milder conditions.

Green catalysts are designed to produce desired products with minimal adverse reactions, enhancing process efficiency and selectivity. For example, biocatalysts such as enzymes offer high selectivity and operate under ambient conditions, making them attractive for sustainable processes. Additionally, the use of Earth-abundant and non-toxic materials in catalyst design reduces the ecological footprint of chemical manufacturing.

The integration of green catalysts in industrial processes supports the global transition to sustainable development goals, particularly in energy production and chemical manufacturing. By employing catalysts that require less energy input and generate fewer byproducts, industries can significantly reduce greenhouse gas emissions and resource depletion, paving the way for a more sustainable future.

The development of recyclable and regenerable catalysts is another noteworthy advancement in green practices. These catalysts can be reused multiple times without significant loss of activity, reducing waste and the need for frequent replacements. Research into recyclable heterogeneous catalysts, for instance, has shown promising results, with materials like metal-organic frameworks (MOFs) offering excellent performance and stability. These advancements ensure that sustainability is not merely an ideal but an achievable goal within the catalytic sciences.

The Future of Catalyst Development: Challenges and Opportunities

Despite remarkable progress, several challenges remain in catalyst development for energy-efficient reactions. One significant hurdle is the scalability of newly developed catalysts from laboratory settings to industrial applications. Many promising materials, such as single-atom catalysts and advanced photocatalysts, are challenging to produce on a large scale while maintaining consistent quality and performance.

Another challenge lies in achieving an optimal balance between cost and efficiency. Advanced catalysts often involve rare or expensive materials, such as platinum-group metals, which can limit their widespread adoption. Research into Earth-abundant alternatives and the development of hybrid systems combining organic and inorganic materials are essential to address this issue.

Opportunities, however, abound. Interdisciplinary collaboration between chemists, material scientists, and engineers offers the potential to overcome these barriers. Machine learning and computational modeling continue to revolutionize the way catalysts are designed, enabling faster discovery and optimization of new materials. Moreover, increasing global emphasis on green energy and sustainability provides a strong impetus for investment and innovation in this field.

Catalysis as the Keystone of a Sustainable Future

Catalyst development for energy-efficient reactions is not merely a scientific endeavor but a cornerstone of global efforts toward sustainability and environmental stewardship. From nanocatalysis and single-atom innovations to machine learning-driven designs and green practices, the field is evolving rapidly, offering solutions to some of the most pressing challenges of our time.

As industries and researchers work together to integrate these advancements into practical applications, catalysts are poised to transform chemical manufacturing, energy production, and environmental conservation. The promise of catalysts is clear: a future where efficiency, sustainability, and innovation converge to create a more harmonious relationship between human progress and the natural world.

Engr. Dex Marco Tiu Guibelondo, B.Sc. Pharm, R.Ph., B.Sc. CpE

Subscribe

to get our

LATEST NEWS

Related Posts

Chemistry, Manufacturing & Controls

Harvesting the Heat: Reclaiming Industrial Energy Losses through Next-Generation Waste Heat Recovery Technologies

Waste heat recovery is now essential—technically sound, economically viable, and environmentally critical.

Chemistry, Manufacturing & Controls

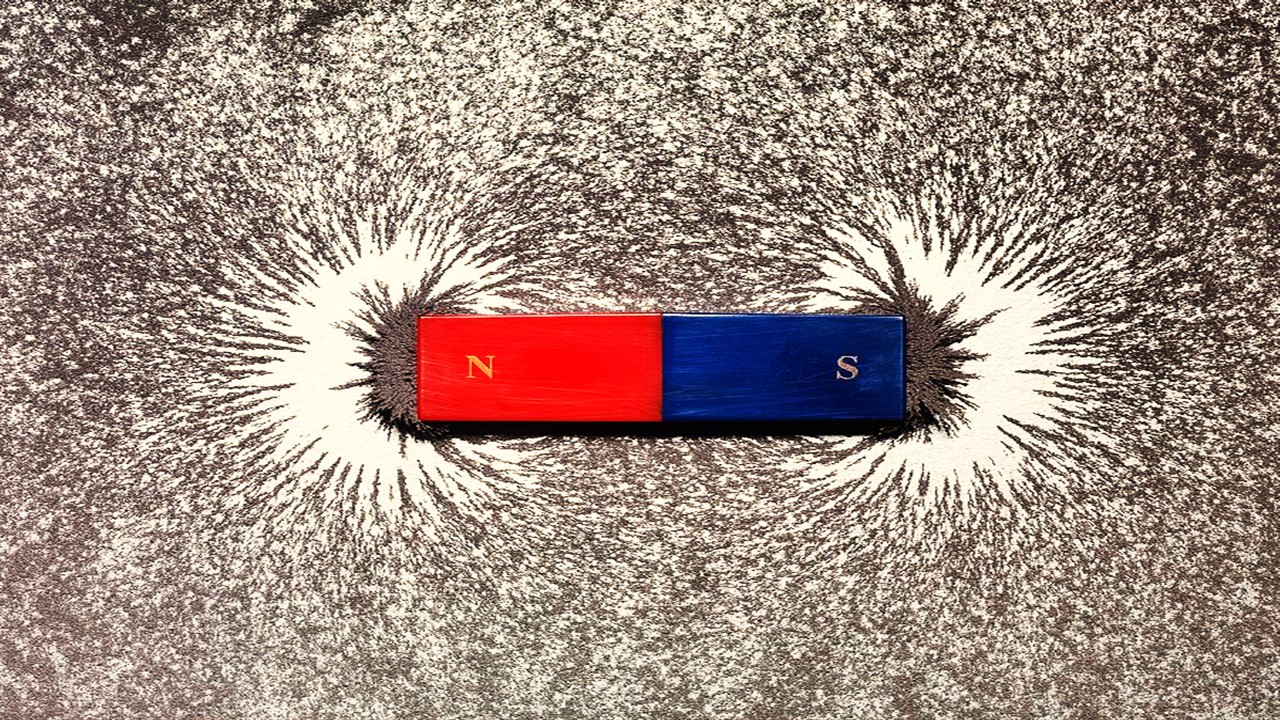

Magnetic Nanoengineering: Overcoming Biological Variability and Enhancing Therapeutic Precision

The future of nanomedicine lies in harmonizing precision, accessibility, and ecological responsibility, ushering in an era where therapies are tailored to individual biological landscapes.

Read More Articles

Myosin’s Molecular Toggle: How Dimerization of the Globular Tail Domain Controls the Motor Function of Myo5a

Myo5a exists in either an inhibited, triangulated rest or an extended, motile activation, each conformation dictated by the interplay between the GTD and its surroundings.