The Bedrock of Modern Medicine

Active Pharmaceutical Ingredients (APIs) lie at the heart of all therapeutic agents, driving the pharmacological efficacy that saves lives and improves health. These molecules are the active components in drugs, directly influencing their ability to combat diseases. Yet, behind the potency of an API lies a formidable challenge: their production often requires the construction of intricate molecular architectures through multi-step organic synthesis. This highly technical process demands the precise orchestration of numerous chemical reactions, each tailored to craft specific functional groups, stereoisomers, and bonds. The process isn’t just about chemistry—it’s about engineering reactions at the molecular level.

The journey from a concept to a tangible API begins with designing a synthetic strategy that transforms simple starting materials into complex, biologically active compounds. This approach must balance the need for economic efficiency with chemical feasibility while navigating regulatory constraints that mandate high purity and minimal environmental impact. As therapeutic demands grow increasingly sophisticated—targeting intricate pathways in cancer, infectious diseases, and rare conditions—the role of multi-step synthesis becomes ever more pivotal in pushing the boundaries of medicine.

In this context, APIs represent more than just molecules. They are the embodiment of years, sometimes decades, of research and innovation in organic chemistry. This article delves into the sophisticated science behind their production, exploring the stages of multi-step synthesis, the challenges involved, and the evolving methods that seek to make these processes more sustainable and efficient.

Strategic Blueprinting: Designing Synthetic Pathways

Designing the synthetic pathway for an API is both a science and an art. Chemists must carefully evaluate the structural complexity of the target molecule and identify the most efficient route to its construction. This begins with retrosynthetic analysis, a process of deconstructing the API into simpler precursor molecules, each corresponding to achievable synthetic steps. This strategy requires a deep understanding of chemical reactivity, bond-forming capabilities, and functional group compatibility to ensure each reaction progresses without compromising subsequent steps.

Key considerations in pathway design include minimizing the number of synthetic steps and maximizing yields at each stage. Fewer steps mean less material loss and reduced waste, translating into cost and time savings. However, the process isn’t always straightforward—molecules with multiple functional groups or stereocenters present unique challenges. Convergent synthesis, where separate molecular fragments are synthesized independently before being joined, is a common approach to address such complexity. It reduces the cumulative risk of yield losses by consolidating key components early in the synthesis.

An equally important factor in designing pathways is the selection of reagents and catalysts. Reagents must drive reactions efficiently, while catalysts, particularly those based on transition metals, enable transformations that would otherwise be infeasible. These tools enable chemists to fine-tune selectivity, ensuring the desired product dominates over unwanted by-products. Balancing all these variables requires not just technical expertise but also the creativity to innovate and adapt in the face of obstacles.

The Crucial Role of Selectivity in API Synthesis

Selectivity lies at the core of successful multi-step synthesis, dictating the efficiency and feasibility of each reaction. Chemists aim to control every aspect of a reaction: which bonds are formed, where they form, and how they orient in three-dimensional space. This begins with chemoselectivity—the ability to target specific functional groups while leaving others untouched. Without this control, undesired side reactions can occur, complicating purification and reducing overall yield.

Regioselectivity, which ensures the formation of bonds at precise locations within a molecule, is another critical aspect. This is particularly relevant in molecules with multiple potential reactive sites. For example, selectively introducing a substituent on a specific position of an aromatic ring demands careful choice of reaction conditions, catalysts, and directing groups. Stereoselectivity, the third pillar of selectivity, governs the spatial arrangement of atoms in chiral molecules. APIs often require specific stereoisomers for biological activity, as even minor deviations in stereochemistry can render a drug ineffective—or worse, toxic.

To achieve such control, chemists rely on a variety of tools. Protecting groups are temporarily introduced to shield reactive sites during intermediate steps, allowing for selective manipulation of other parts of the molecule. Catalysts, ranging from organometallic complexes to enzymes, provide a level of precision that is unattainable through traditional reagents. These advancements not only enhance selectivity but also reduce the need for extensive purification, streamlining the entire synthetic process.

Flow Chemistry: Revolutionizing API Manufacturing

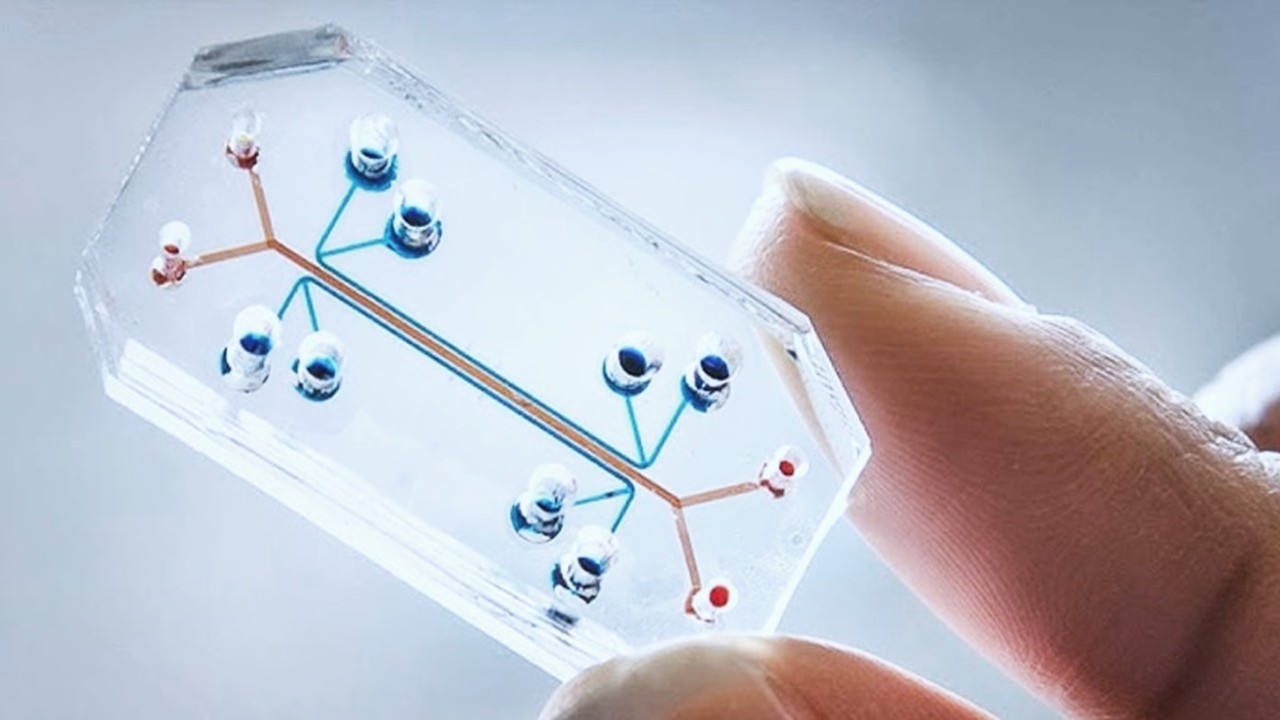

The advent of flow chemistry has introduced a revolutionary approach to API synthesis, transforming the traditional batch process. In batch systems, reactions occur in a single vessel, requiring careful monitoring and manual transfers between steps. In contrast, flow chemistry operates continuously, with reactants moving through a series of interconnected reactors. This setup allows for unparalleled control over reaction parameters, such as temperature, pressure, and mixing efficiency, enabling conditions that are difficult or unsafe to achieve in batch systems.

One of the key advantages of flow chemistry is its ability to handle hazardous reactions. In batch processes, scaling up exothermic or highly reactive transformations poses significant safety risks. Flow systems, by limiting the reaction volume at any given time, mitigate these dangers while maintaining scalability. This is particularly beneficial in API production, where reactions often involve sensitive intermediates or require precise control over kinetics.

Flow chemistry also facilitates integration of multiple reaction steps, reducing the need for intermediate isolations. This not only saves time but also minimizes material losses, improving overall efficiency. Additionally, the modular nature of flow reactors makes them highly adaptable, allowing for quick reconfiguration to accommodate different APIs or process optimizations. As pharmaceutical companies increasingly adopt this technology, it promises to revolutionize how APIs are synthesized and manufactured.

Biocatalysis: Enzymes as Molecular Machines

Biocatalysis has emerged as a powerful tool in multi-step API synthesis, harnessing the specificity and efficiency of natural enzymes. These biological catalysts excel at performing reactions with high selectivity, particularly in creating chiral centers—a common requirement in API structures. Enzymes offer unparalleled control over enantioselectivity, allowing for the production of stereochemically pure compounds that are critical for drug efficacy and safety.

One of the most significant advantages of biocatalysis is its alignment with green chemistry principles. Enzymes operate under mild conditions, often requiring only water as a solvent and ambient temperatures. This reduces the environmental footprint of chemical manufacturing, as well as the reliance on toxic reagents and solvents. Furthermore, enzymes can be engineered through techniques like directed evolution to perform reactions outside their natural scope, expanding their utility in synthetic chemistry.

Applications of biocatalysis in API production are already making waves. For example, the use of engineered enzymes in the synthesis of statins, a class of cholesterol-lowering drugs, has simplified production while improving yield and sustainability. By integrating biocatalysts into multi-step synthesis, chemists can achieve levels of efficiency and specificity that were once thought impossible.

Sustainability in API Synthesis: Green Chemistry in Action

Sustainability has become a central focus in API production, driven by the need to reduce environmental impact and comply with regulatory demands. Green chemistry principles emphasize minimizing waste, improving energy efficiency, and using renewable resources wherever possible. In multi-step synthesis, this often involves replacing traditional reagents with safer, more sustainable alternatives and optimizing reaction conditions to maximize atom economy.

Catalysis plays a pivotal role in these efforts. Transition-metal catalysts, while effective, often rely on rare and toxic metals. Efforts to develop recyclable or biodegradable catalysts are gaining traction, as are bio-based solvents that replace hazardous organic compounds. Similarly, continuous flow systems, by integrating reaction steps and reducing material losses, contribute to more sustainable processes.

Another promising avenue is the use of renewable feedstocks. Rather than relying on petrochemicals, chemists are exploring biomass-derived starting materials, which offer a renewable and often less expensive alternative. By aligning synthetic strategies with these principles, the pharmaceutical industry can make API production not only more sustainable but also more economically viable in the long term.

Pioneering the Future of API Synthesis

The synthesis of APIs through multi-step organic synthesis is a testament to the ingenuity and perseverance of modern chemistry. As therapeutic targets grow more complex, the methods for crafting these molecules must evolve, incorporating advanced technologies and sustainable practices. The integration of flow chemistry, biocatalysis, and green chemistry principles represents just the beginning of this transformation.

Looking ahead, the future of API synthesis will likely be shaped by further advancements in automation, machine learning, and renewable chemistry. These innovations hold the promise of making drug development faster, safer, and more accessible, ensuring that life-saving medications reach those who need them most. By embracing this convergence of science and sustainability, the pharmaceutical industry can continue to push the boundaries of what is possible in medicine.

Engr. Dex Marco Tiu Guibelondo, B.Sc. Pharm, R.Ph., B.Sc. CpE

Subscribe

to get our

LATEST NEWS

Related Posts

Manufacturing & Logistics

Streamlining Pharmaceutical Synthesis: The Science of Process Intensification in High-Yield API Production

As the industry embraces QbD, PAT, and Pharma 4.0, process intensification will redefine the future of pharmaceutical manufacturing.

Manufacturing & Logistics

Modern Supply Chain Dynamics: Integrating Real-Time Logistics with Blockchain Technology

The convergence of real-time logistics systems and blockchain technology is still in its nascent stages, but the trajectory is promising.

Read More Articles

Myosin’s Molecular Toggle: How Dimerization of the Globular Tail Domain Controls the Motor Function of Myo5a

Myo5a exists in either an inhibited, triangulated rest or an extended, motile activation, each conformation dictated by the interplay between the GTD and its surroundings.