Introduction to Biocatalysis in Chemical Manufacturing

In the quest for sustainable industrial processes, biocatalysis has emerged as a pivotal technology, leveraging natural catalysts—enzymes—to facilitate chemical reactions. These biological molecules offer remarkable specificity and efficiency, enabling the transformation of substrates into desired products under mild conditions. This approach not only reduces energy consumption but also minimizes the generation of hazardous by-products, aligning with the principles of green chemistry.

The integration of biocatalysis into chemical manufacturing represents a paradigm shift from traditional methods that often rely on harsh chemicals and extreme conditions. By mimicking nature’s own processes, industries can achieve higher selectivity and yield, paving the way for more sustainable production pathways. This transition is particularly significant in the synthesis of complex molecules, where conventional chemical routes may falter in efficiency or selectivity.

Moreover, advancements in biotechnology have facilitated the engineering of enzymes with tailored properties, enhancing their stability and activity under industrial conditions. Such innovations have expanded the applicability of biocatalysis across various sectors, including pharmaceuticals, agrochemicals, and biofuels, underscoring its versatility as a tool for sustainable development.

Enzyme Engineering: Tailoring Catalysts for Industrial Applications

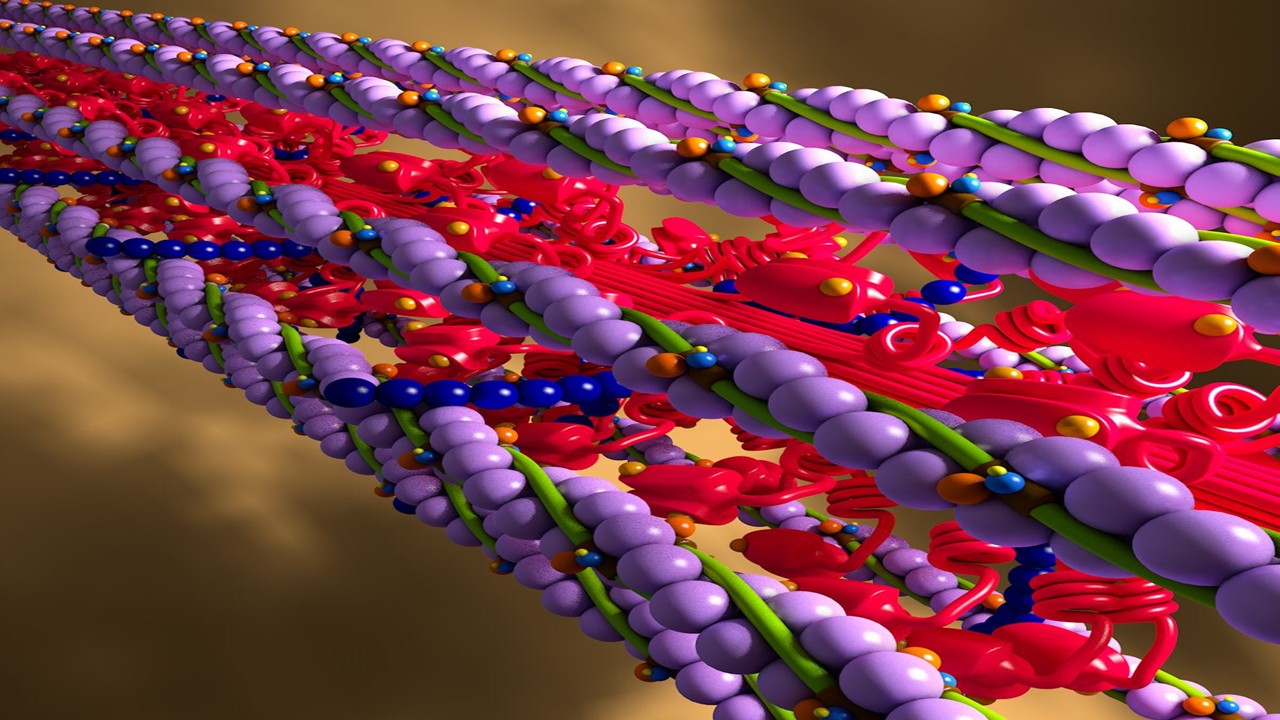

The efficacy of biocatalysis in industrial applications hinges on the ability to engineer enzymes that meet specific process requirements. Through techniques such as directed evolution and rational design, scientists can modify enzyme structures to enhance their performance characteristics, including substrate specificity, catalytic efficiency, and operational stability. These engineered enzymes can operate under conditions that were previously prohibitive, such as high temperatures, extreme pH levels, or the presence of organic solvents.

For instance, the development of cross-linked enzyme aggregates (CLEAs) represents a significant advancement in enzyme immobilization, offering a method that enhances both stability and reusability. This technique involves the precipitation of enzymes into densely packed aggregates, followed by cross-linking with bifunctional agents, which creates a rigid, insoluble structure. CLEAs not only preserve high catalytic activity but also exhibit superior resistance to thermal and chemical denaturation, making them ideal for industrial applications. Additionally, the immobilization within CLEAs facilitates easy recovery and reuse of enzymes, reducing operational costs and increasing process efficiency.

The rise of computational tools has revolutionized enzyme engineering, making it faster and more precise. In silico modeling, which involves using computer simulations, allows scientists to visualize and predict enzyme-substrate interactions at the molecular level. This technology enables the identification of key structural features and potential modification sites that may enhance enzyme efficiency or stability. This synergy between computational and experimental approaches streamlines the development of bespoke biocatalysts tailored to specific industrial needs.

Biocatalytic Processes in Pharmaceutical Manufacturing

The pharmaceutical industry has been a prominent beneficiary of biocatalysis, utilizing enzymes to synthesize active pharmaceutical ingredients (APIs) with high enantiomeric purity. Enzymatic processes offer superior stereoselectivity compared to traditional chemical methods, which is crucial in the production of chiral drugs where the desired therapeutic activity is often associated with a specific enantiomer.

A notable example is the synthesis of sitagliptin (sold under the brand name Januvia), an API used in the treatment of type 2 diabetes. Sitagliptin is in the dipeptidyl peptidase-4 (DPP-4) inhibitor class and works by increasing the production of insulin and decreasing the production of glucagon by the pancreas. Traditional chemical synthesis of sitagliptin involved multiple steps with moderate yields and significant waste generation. By employing an engineered transaminase enzyme, the biocatalytic route streamlined the process into a single step, enhancing yield and reducing environmental impact. This case exemplifies how biocatalysis can revolutionize pharmaceutical manufacturing by making it more efficient and sustainable.

Additionally, biocatalysis enables the late-stage functionalization of complex molecules, allowing for the introduction of functional groups at specific positions with high precision. This capability is particularly valuable in drug development, where structural modifications can significantly influence pharmacological properties. The use of enzymes in such transformations not only simplifies the synthetic route but also reduces the reliance on protecting groups and harsh reagents, further aligning with green chemistry principles.

Biocatalysis in the Production of Fine Chemicals and Agrochemicals

Beyond pharmaceuticals, biocatalysis has found applications in the synthesis of fine chemicals and agrochemicals, sectors that demand high specificity and purity in their products. Flavin-dependent enzymes such as Baeyer-Villiger monooxygenases (BVMOs) have been employed to catalyze oxidation reactions, converting ketones into esters or lactones with high regioselectivity and enantioselectivity. These reactions are challenging to achieve with traditional chemical catalysts without resorting to multiple steps and protective group strategies.

In the agrochemical industry, biocatalysis facilitates the production of herbicides and pesticides with reduced environmental impact. For example, the enzymatic synthesis of chiral intermediates used in the formulation of selective herbicides ensures that the active compounds are both effective and biodegradable. This approach not only improves the safety profile of agrochemicals but also addresses regulatory pressures aimed at minimizing ecological footprints.

Moreover, the use of biocatalysts in these industries often results in processes that are more atom-economical, meaning a higher proportion of reactants are converted into the desired product. This efficiency reduces waste and lowers production costs, making biocatalysis an economically attractive option for manufacturers seeking to adopt sustainable practices.

Integration of Biocatalysis in Biofuel Production

The pursuit of renewable energy sources has led to the exploration of biocatalysis in biofuel production. Enzymes such as lipases and cellulases play critical roles in the transesterification of oils and the hydrolysis of lignocellulosic biomass, respectively, facilitating the conversion of renewable resources into biodiesel and bioethanol. These biocatalytic processes operate under milder conditions compared to chemical catalysts, reducing energy input and minimizing the formation of undesirable by-products.

In biodiesel production, lipases catalyze the transesterification of triglycerides into fatty acid methyl esters (FAMEs), the primary constituents of biodiesel. Traditional chemical methods require high temperatures and strong acids or bases, leading to issues such as soap formation and difficulties in glycerol separation. Lipase-catalyzed processes, on the other hand, offer higher specificity and can utilize a broader range of feedstocks, including waste oils, thereby enhancing the sustainability of biodiesel production.

Similarly, in bioethanol production, cellulases break down lignocellulosic biomass—an abundant and renewable source of sugars—into fermentable sugars. These sugars are subsequently fermented into ethanol by microorganisms such as yeast. The enzymatic hydrolysis step, often the most challenging, is made more efficient with advances in enzyme engineering. For example, cellulases with enhanced activity and stability have significantly improved the feasibility of large-scale lignocellulosic bioethanol production. Such biocatalytic innovations are critical for making biofuels competitive with fossil fuels, addressing both economic and environmental concerns.

Overcoming Challenges in Scaling Biocatalysis

While the potential of biocatalysis in chemical manufacturing is undeniable, its industrial adoption is not without challenges. One of the primary hurdles lies in the scalability of enzymatic processes. Unlike traditional chemical catalysts, enzymes are inherently fragile and can lose activity under extreme industrial conditions, such as high temperatures, pressures, or the presence of organic solvents. Developing robust enzymes that can withstand these conditions is a key focus of current research.

Enzyme immobilization techniques, such as encapsulation or covalent attachment to solid supports, offer promising solutions. Immobilization not only enhances enzyme stability but also facilitates their recovery and reuse, which is essential for cost-effective industrial applications. Additionally, biocatalyst optimization through high-throughput screening and molecular evolution ensures the development of enzymes tailored for specific industrial needs.

Another challenge is the high cost associated with enzyme production and purification. Advances in microbial fermentation and synthetic biology have addressed this issue by enabling the overexpression of enzymes in host organisms like Escherichia coli or yeast (Saccharomyces cerevisiae). Coupled with downstream processing innovations, these developments have significantly reduced the cost of biocatalysts, making them more accessible to industry.

Furthermore, integrating biocatalytic steps into existing chemical manufacturing workflows often requires reengineering the process design. Collaboration between biologists, chemists, and process engineers is vital to ensure that biocatalytic processes are seamlessly integrated, maximizing their efficiency and sustainability.

Biocatalysis and Sustainability: A Green Chemistry Perspective

Biocatalysis epitomizes the principles of green chemistry, offering an environmentally friendly alternative to traditional chemical manufacturing. Enzymatic reactions typically occur under mild conditions—ambient temperatures, neutral pH levels, and aqueous solvents—substantially reducing the energy demand and the use of hazardous chemicals. This contrasts sharply with conventional catalytic methods, which often rely on harsh reagents and generate significant waste.

A major advantage of biocatalysis is its unparalleled selectivity, which minimizes the formation of unwanted by-products. This high specificity translates into better atom economy, as more of the starting materials are converted into the desired products. By reducing waste at the source, biocatalysis addresses one of the core tenets of sustainable chemistry.

Additionally, the use of renewable resources as feedstocks in biocatalytic processes further enhances their sustainability. For example, agricultural residues and food waste can serve as substrates for enzymatic conversion into value-added products, such as biofuels, bioplastics, and fine chemicals. This not only provides an alternative to fossil-based raw materials but also contributes to waste valorization and circular economy practices.

Looking forward, the scalability of biocatalysis will be critical in addressing global challenges such as climate change and resource scarcity. The adoption of enzymatic processes in industries ranging from pharmaceuticals to energy is a testament to their potential to drive sustainable innovation across sectors.

Future Horizons: Biocatalysis as a Cornerstone of Industrial Innovation

The future of biocatalysis lies in its integration with other cutting-edge technologies, such as artificial intelligence (AI), machine learning (ML), and synthetic biology. AI and ML are already revolutionizing enzyme design by enabling the prediction of enzyme-substrate interactions and optimizing catalytic performance. These tools significantly accelerate the discovery of novel biocatalysts, reducing the time and cost of development.

Synthetic biology further expands the possibilities by creating entirely new enzymes and metabolic pathways. By engineering microorganisms to produce specific enzymes or even directly synthesize target molecules, researchers are unlocking new frontiers in biocatalysis. These engineered systems promise to overcome many limitations of current biocatalytic processes, such as substrate scope and operational stability.

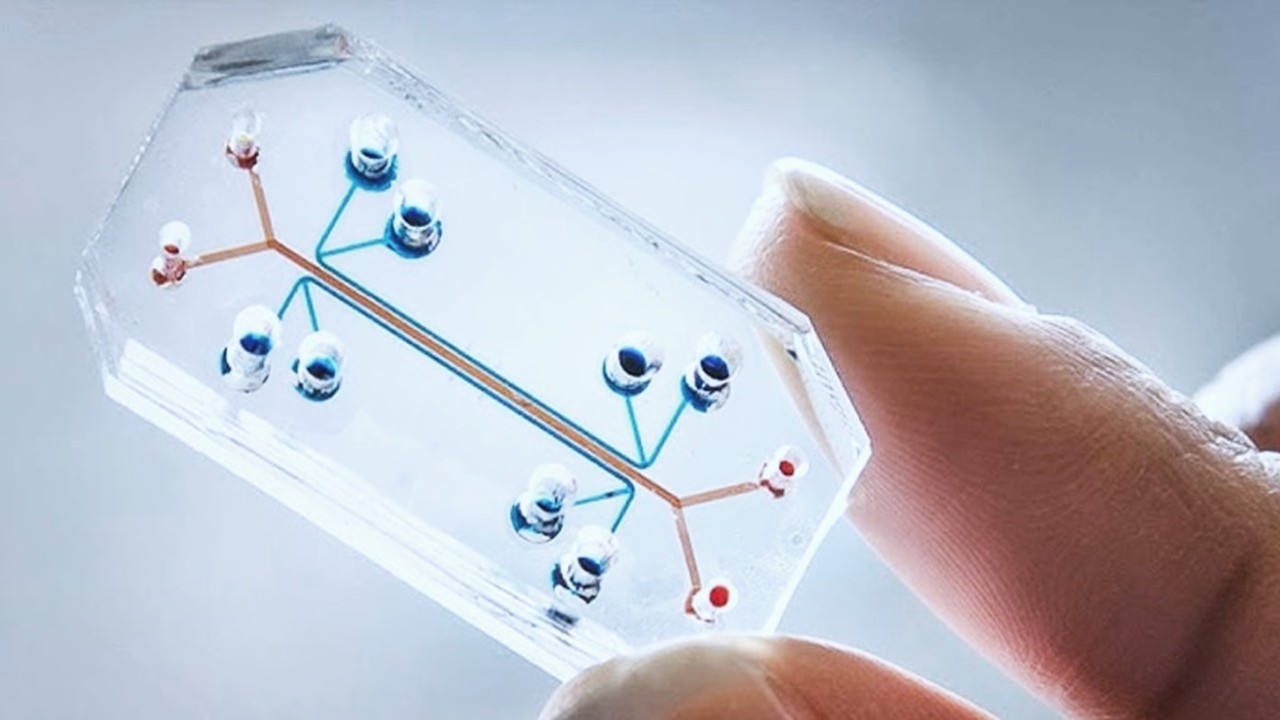

Moreover, the integration of biocatalysis with other green technologies, such as flow chemistry and bioprocess intensification, will pave the way for more efficient and sustainable manufacturing. By combining the precision of biocatalysis with the scalability of continuous processing, industries can achieve unprecedented levels of productivity and environmental performance.

As the world grapples with the dual challenges of environmental degradation and resource scarcity, biocatalysis offers a beacon of hope. By harnessing nature’s own tools, we can reimagine chemical manufacturing in a way that is both economically viable and ecologically responsible. The enzymatic alchemy of biocatalysis is not just a scientific breakthrough—it is a call to action for industries to embrace sustainability at their core.

Engr. Dex Marco Tiu Guibelondo, B.Sc. Pharm, R.Ph., B.Sc. CpE

Editor-in-Chief, PharmaFEATURES

Subscribe

to get our

LATEST NEWS

Related Posts

Chemistry, Manufacturing & Controls

Harvesting the Heat: Reclaiming Industrial Energy Losses through Next-Generation Waste Heat Recovery Technologies

Waste heat recovery is now essential—technically sound, economically viable, and environmentally critical.

Chemistry, Manufacturing & Controls

Magnetic Nanoengineering: Overcoming Biological Variability and Enhancing Therapeutic Precision

The future of nanomedicine lies in harmonizing precision, accessibility, and ecological responsibility, ushering in an era where therapies are tailored to individual biological landscapes.

Read More Articles

Myosin’s Molecular Toggle: How Dimerization of the Globular Tail Domain Controls the Motor Function of Myo5a

Myo5a exists in either an inhibited, triangulated rest or an extended, motile activation, each conformation dictated by the interplay between the GTD and its surroundings.