The pharmaceutical industry stands at the crossroads of innovation and responsibility. As environmental concerns escalate, the pressure to adopt sustainable manufacturing practices grows ever more pressing. Among these, the green synthesis of active pharmaceutical ingredients (APIs) emerges as a cornerstone. This approach combines the principles of green chemistry and engineering to minimize environmental harm while maintaining the high efficacy and quality standards demanded by modern medicine. In this comprehensive exploration, we will dissect the key elements of green API synthesis, shedding light on the transformative impact it holds for the industry and beyond.

Principles of Green Chemistry in API Synthesis

Green chemistry, a framework introduced to revolutionize traditional chemical processes, emphasizes reducing hazardous substances’ use and generation. For API synthesis, this involves a meticulous reevaluation of the entire production pipeline. First, the focus shifts to designing processes that maximize atom economy—ensuring that the majority of reactants are converted into the desired product, thereby minimizing waste. Second, catalysis takes center stage, with an emphasis on developing selective catalysts that drive reactions efficiently and cleanly.

Moreover, reaction conditions are carefully optimized to reduce energy requirements. Lower reaction temperatures and pressures translate into smaller carbon footprints, aligning with sustainability goals. Finally, the adoption of safer reagents and solvents ensures that the manufacturing process is not only efficient but also safe for workers and the environment. By integrating these principles, green chemistry paves the way for a new era in pharmaceutical production.

The emphasis on minimizing environmental impact does not compromise innovation. Researchers have developed groundbreaking synthetic routes that outperform traditional methods in yield and efficiency. For instance, leveraging renewable feedstocks—materials derived from biological sources like plants or algae—has opened new pathways for API production, ensuring a sustainable and reliable supply chain.

Despite its promise, the implementation of green chemistry in API synthesis is not without challenges. Scaling laboratory successes to industrial processes often requires significant investment in research and infrastructure. Yet, the potential for long-term cost savings and regulatory compliance makes this approach a compelling choice for forward-thinking pharmaceutical companies.

Solvent Selection and Alternative Reaction Media

One of the most significant contributors to environmental impact in pharmaceutical synthesis is solvent use. Traditional solvents, such as dichloromethane or toluene, are not only toxic but also pose significant disposal challenges. Green synthesis advocates for the adoption of alternative solvents that are less harmful to both humans and ecosystems. Water, often termed the “universal solvent,” has seen a resurgence in its application for organic reactions, providing a safe and cost-effective medium.

Beyond water, bio-based solvents derived from agricultural byproducts offer promising alternatives. These include ethyl lactate and glycerol, which are biodegradable and non-toxic. Furthermore, the development of ionic liquids and deep eutectic solvents (DES) has revolutionized green chemistry. These novel media exhibit unique properties, such as negligible vapor pressure and tunable solubility, making them ideal for various chemical transformations.

Solvent-free reactions represent another frontier in sustainable synthesis. Techniques such as mechanochemistry, which employs mechanical energy to drive reactions, eliminate the need for solvents altogether. This approach not only reduces waste but also simplifies the purification process, further enhancing efficiency.

While the adoption of greener solvents and solvent-free techniques marks significant progress, their implementation requires overcoming technical and economic barriers. Industries must invest in retraining personnel, retrofitting equipment, and conducting extensive safety evaluations. Nevertheless, the environmental and operational benefits far outweigh these initial hurdles, making this a critical area for future development.

Biocatalysis and Enzymatic Engineering

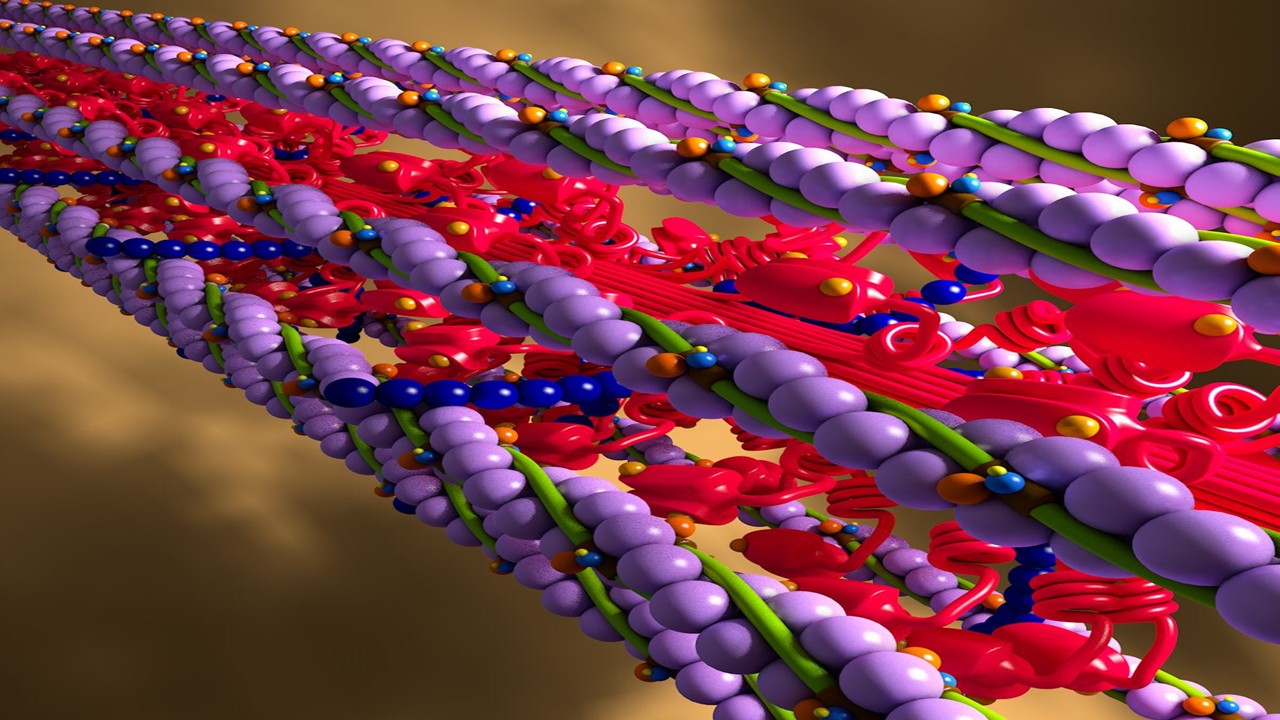

Biocatalysis harnesses the catalytic power of enzymes to perform chemical transformations with remarkable precision and efficiency. In API synthesis, this approach offers a sustainable alternative to traditional chemical catalysts, often requiring harsh conditions or generating significant waste. Enzymes, by contrast, operate under mild conditions and exhibit unparalleled selectivity, reducing the need for extensive purification steps.

The potential of biocatalysis is exemplified by the production of artemisinin, a vital antimalarial drug. Traditional extraction from the Artemisia annua plant is labor-intensive and subject to agricultural variability. By engineering microorganisms to biosynthesize artemisinic acid, researchers have created a scalable, renewable source for this API, ensuring consistent global supply.

Another area of innovation lies in enzymatic engineering, where scientists modify enzymes to enhance their stability and activity. Directed evolution—a method mimicking natural selection in the laboratory—has yielded enzymes capable of performing complex reactions previously thought impossible. These advancements have expanded the scope of biocatalysis, enabling its application to an ever-growing range of APIs.

Despite these successes, challenges remain. Enzyme production can be costly, and their integration into industrial processes often requires significant optimization. However, ongoing advancements in synthetic biology and process engineering promise to overcome these barriers, solidifying biocatalysis as a cornerstone of green API synthesis.

Process Intensification and Continuous Manufacturing

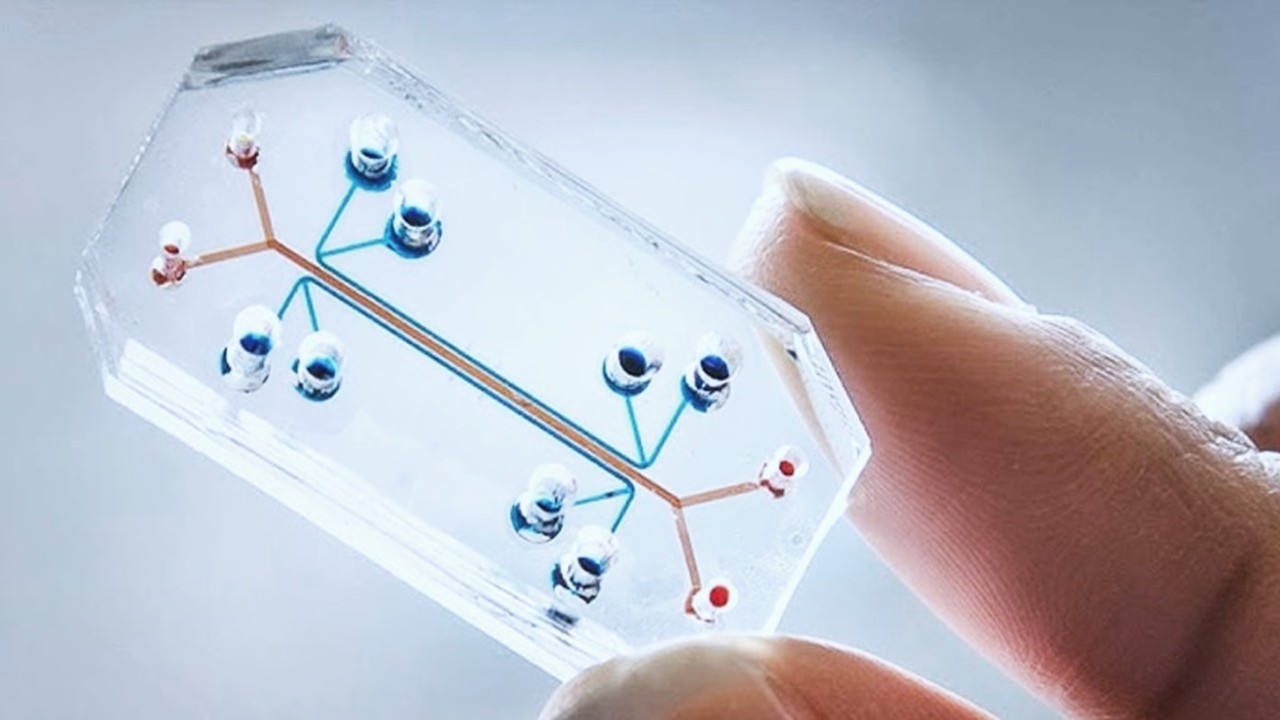

Traditional batch processing in pharmaceutical manufacturing is often resource-intensive and prone to inefficiencies. Process intensification aims to address these issues by redesigning manufacturing systems to enhance efficiency, reduce energy consumption, and minimize waste. Continuous manufacturing—a key component of this approach—has gained traction as a sustainable alternative to batch processes.

In continuous manufacturing, raw materials are fed into a system that operates non-stop, producing APIs in a steady stream. This method offers several advantages, including reduced equipment size, shorter production times, and improved product quality. Additionally, continuous processes are inherently safer, as they require smaller quantities of reactive intermediates at any given time.

The adoption of microreactors has further revolutionized continuous manufacturing. These compact devices enable precise control over reaction parameters, such as temperature and pressure, enhancing reaction efficiency and safety. For example, microreactors have been employed to synthesize APIs like ibuprofen and paracetamol, achieving higher yields with reduced environmental impact.

While the transition to continuous manufacturing represents a paradigm shift, it necessitates substantial investment in infrastructure and regulatory adaptation. Collaborative efforts between academia, industry, and regulatory agencies will be crucial to realizing its full potential, ensuring that sustainability becomes a standard in pharmaceutical production.

Multicomponent Reactions and Atom Economy

Multicomponent reactions (MCRs) are a hallmark of green chemistry, enabling the construction of complex molecules in a single step. By combining three or more reactants into one reaction vessel, MCRs maximize atom economy and minimize waste. This approach has found particular utility in API synthesis, where efficiency and precision are paramount.

The appeal of MCRs lies in their versatility. They can be tailored to produce a wide range of molecular scaffolds, making them invaluable for drug discovery and development. Moreover, their streamlined nature reduces the need for intermediate purification, saving time and resources.

Recent advancements in MCR methodology have expanded their applicability to challenging substrates and reaction conditions. For instance, the use of microwave irradiation and flow chemistry has enhanced reaction rates and yields, bringing MCRs closer to industrial viability.

Despite their advantages, MCRs are not without limitations. Reaction conditions must be carefully optimized to avoid side reactions, and the scalability of some MCRs remains a challenge. However, ongoing research continues to address these issues, ensuring that MCRs play a pivotal role in the future of green API synthesis.

Challenges and Future Directions

The transition to green API synthesis is not without obstacles. Economic considerations often deter companies from adopting new technologies, as the initial investment can be substantial. Regulatory frameworks, designed with traditional manufacturing in mind, may also impede the implementation of innovative practices.

To overcome these barriers, industry stakeholders must prioritize collaboration and knowledge sharing. Public-private partnerships can accelerate the development and deployment of green technologies, while regulatory agencies must adapt their frameworks to support sustainable innovation.

Education and training are equally critical. By equipping the next generation of chemists and engineers with the tools and knowledge to implement green practices, the industry can ensure a sustainable future. Initiatives such as green chemistry curricula and interdisciplinary research programs are already paving the way.

Green synthesis methods for APIs no doubt represent a transformative opportunity for the pharmaceutical industry. By embracing sustainability, the industry can not only reduce its environmental impact but also enhance efficiency, ensure regulatory compliance, and meet the growing demand for eco-friendly products. The path forward will require ingenuity, collaboration, and perseverance, but the potential rewards—for both humanity and the planet—are immeasurable.

Engr. Dex Marco Tiu Guibelondo, B.Sc. Pharm, R.Ph., B.Sc. CpE

Subscribe

to get our

LATEST NEWS

Related Posts

Chemistry, Manufacturing & Controls

Harvesting the Heat: Reclaiming Industrial Energy Losses through Next-Generation Waste Heat Recovery Technologies

Waste heat recovery is now essential—technically sound, economically viable, and environmentally critical.

Chemistry, Manufacturing & Controls

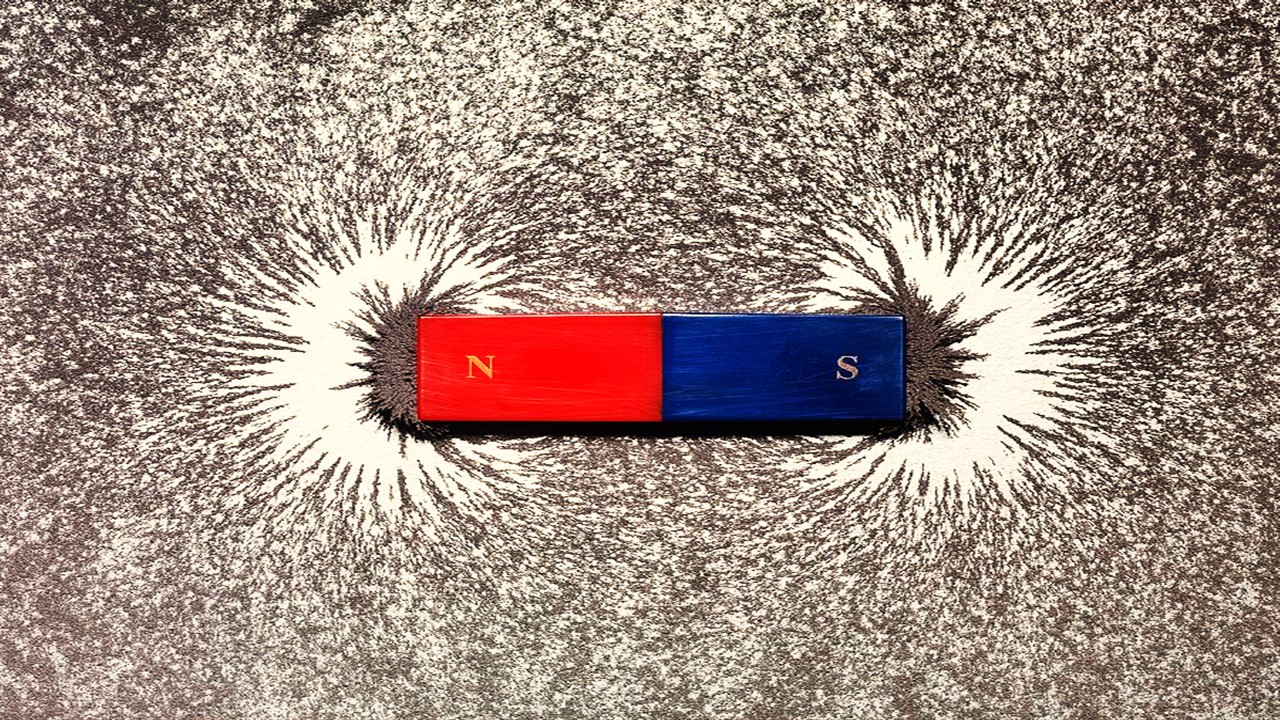

Magnetic Nanoengineering: Overcoming Biological Variability and Enhancing Therapeutic Precision

The future of nanomedicine lies in harmonizing precision, accessibility, and ecological responsibility, ushering in an era where therapies are tailored to individual biological landscapes.

Read More Articles

Myosin’s Molecular Toggle: How Dimerization of the Globular Tail Domain Controls the Motor Function of Myo5a

Myo5a exists in either an inhibited, triangulated rest or an extended, motile activation, each conformation dictated by the interplay between the GTD and its surroundings.