The Fundamental Mechanics of Catalysis in API Synthesis

Catalysts serve as the silent orchestrators of active pharmaceutical ingredient (API) manufacturing, accelerating reactions while remaining unconsumed. Their ability to lower activation energy transforms sluggish chemical processes into rapid, high-yield syntheses. In multi-step API pathways, catalysts enable selective bond formation, minimizing unwanted byproducts. For example, palladium complexes facilitate cross-couplings that stitch aromatic rings—a cornerstone of many small-molecule drugs.

Modern catalysis extends beyond traditional transition metals. Organocatalysts, such as proline derivatives, now mediate asymmetric syntheses critical for chiral APIs. These metal-free systems avoid toxicity concerns while achieving enantiomeric excesses rivaling enzymatic methods. The shift toward atom-economical reactions—where catalysts ensure maximal incorporation of starting materials—has reshaped industrial retrosynthetic planning.

Catalyst recovery and reuse further enhance efficiency. Immobilized catalysts on silica or polymer supports enable continuous-flow systems, reducing batch-to-batch variability. Innovations in magnetic nanoparticles allow catalysts to be retrieved effortlessly via external fields, slashing costs in oncology drug production. Such advancements underscore catalysis as the linchpin of sustainable API manufacturing.

Precision Engineering in Catalyst Design

The advancement of catalyst design is increasingly driven by the integration of computational quantum mechanics and machine learning techniques. Density Functional Theory (DFT) simulations play a pivotal role in this process by enabling the prediction of electron configurations and their impact on catalytic activity. This predictive capability guides the rational design and synthesis of tailored molecular architectures, allowing researchers to optimize catalysts in silico before experimental validation. For instance, DFT calculations have been employed to understand crucial catalytic aspects that are challenging to access experimentally, thereby contributing to the development of more efficient and selective catalysts.

In parallel, machine learning models are being utilized to reduce the computational cost associated with reaction thermochemistry calculations, thereby enabling efficient catalyst screening. By training algorithms on existing data, these models can predict catalytic behaviors and guide the selection of promising catalyst candidates for further study. This approach accelerates the discovery process by focusing experimental efforts on the most promising leads.

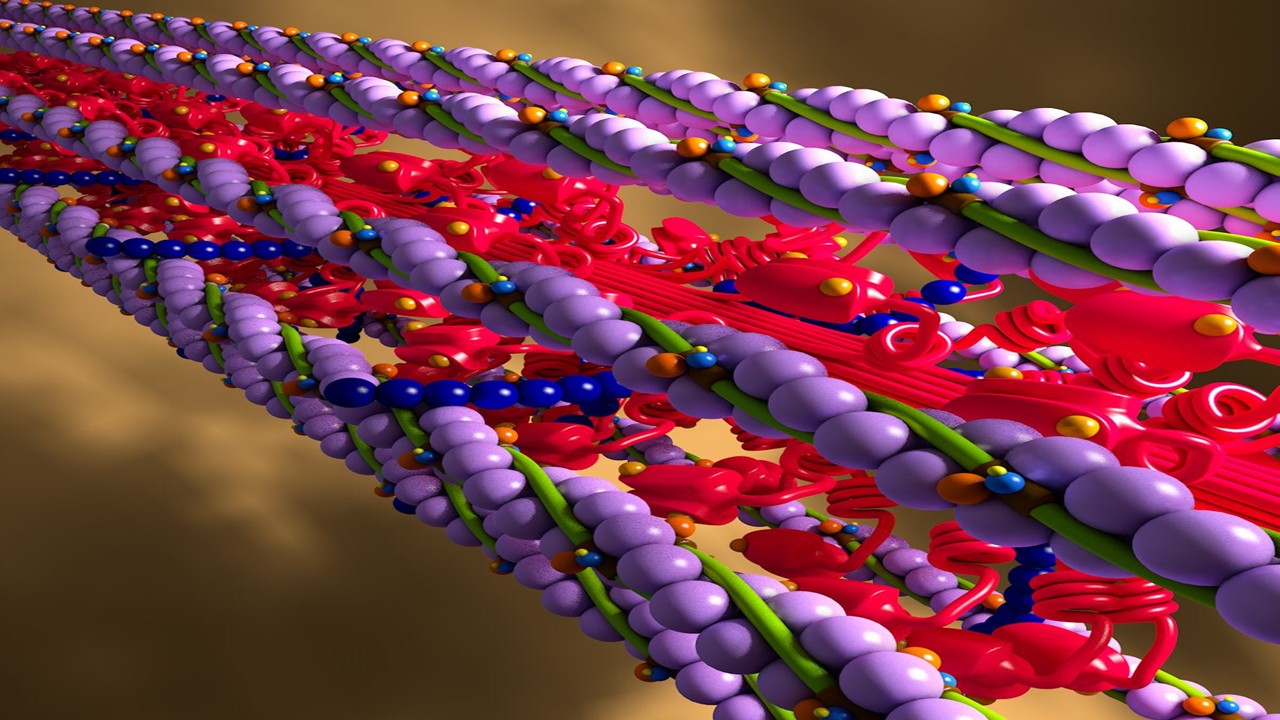

The design of nanostructured catalysts focuses on various aspects such as composition regulation, size optimization, morphology control, and structural engineering. These catalysts exploit high surface-area-to-volume ratios to enhance reactivity, allowing for efficient catalysis under milder conditions. For example, gold nanoparticles have been shown to catalyze oxidation reactions under mild conditions, which is beneficial for preserving heat-sensitive intermediates in pharmaceutical synthesis.

Additionally, mesoporous materials with tailored pore sizes have been developed to selectively admit specific substrates while preventing catalyst deactivation by larger, potentially harmful molecules. This selective permeability is particularly advantageous in complex organic syntheses, where catalyst poisoning can be a significant challenge.

Ligand engineering offers another avenue for refining catalytic specificity and efficiency. By designing ligands that can modulate the electronic environment of the metal center, chemists can steer reactions toward desired products with greater selectivity. For instance, the use of redox-active ligands has enabled iron-catalyzed C–H activation reactions, providing a cost-effective alternative to precious metal catalysts. These advancements have the potential to make high-value active pharmaceutical ingredients more accessible.

Collectively, these innovations underscore a multidisciplinary approach to catalyst design, combining theoretical predictions with experimental validation to develop efficient and selective catalytic systems.

Heterogeneous vs. Homogeneous Catalysis: A Strategic Dilemma

In active pharmaceutical ingredient (API) manufacturing, heterogeneous catalysts—solid materials such as zeolites and metal oxides—are favored for their ease of separation from reaction mixtures. For instance, fixed-bed reactors employing titanium silicalite-1 facilitate continuous hydroxylation processes essential for steroid API production, maintaining operations over extended periods. However, these systems often encounter challenges like diffusional limitations and restricted access to active sites, which can impede reaction efficiency.

Conversely, homogeneous catalysts, which are soluble in the reaction medium, provide advantages in selectivity and operate under milder conditions. A notable example is the use of iridium complexes in the asymmetric hydrogenation of ketones, a critical step in synthesizing β-blockers. Despite these benefits, issues such as metal leaching and the complexity of catalyst recovery present significant obstacles. To address these concerns, innovative biphasic systems have been developed, wherein catalysts are dissolved in ionic liquids separate from the organic solvents, thereby reducing leaching and simplifying recovery processes.

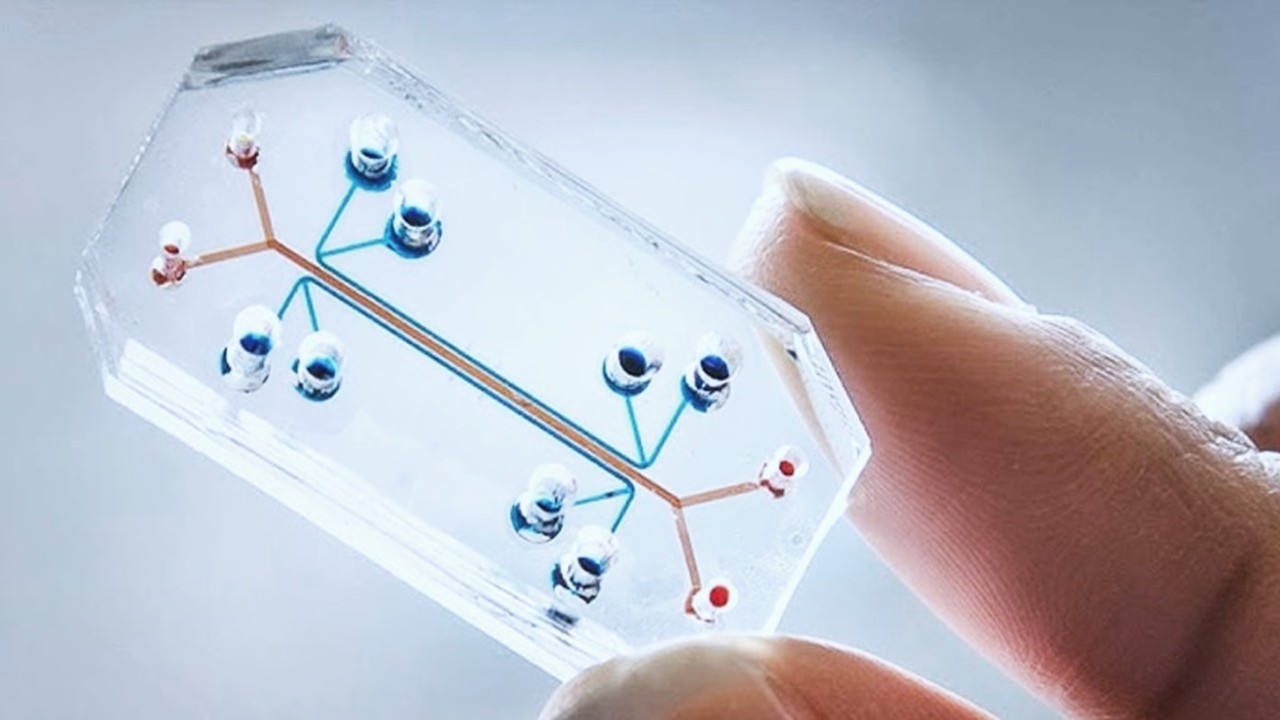

Integrating flow chemistry with immobilized catalysts offers a synergistic approach, combining the strengths of both heterogeneous and homogeneous systems. Microreactors equipped with immobilized enzymes or metal catalysts enhance mixing and heat transfer, expediting reactions like nitration, which are vital in the production of cardiovascular drugs. The pharmaceutical industry is increasingly adopting these hybrid models due to their scalability and reduced environmental impact, marking a significant advancement in efficient and sustainable API synthesis.

Biocatalysts and Enzymatic Renaissance

Enzymes, nature’s catalysts, are reclaiming prominence in active pharmaceutical ingredient (API) synthesis. Engineered transaminases, a class of enzymes, facilitate the conversion of ketones to chiral amines, thereby streamlining the production of antidepressants. Through directed evolution, which involves iterative cycles of mutagenesis and selection, enzyme active sites are tailored for enhanced specificity and efficiency. A notable application of this approach is in the synthesis of the diabetes medication sitagliptin, where a traditional rhodium-catalyzed step was successfully replaced with a biocatalytic process, resulting in a more sustainable and efficient pathway.

Whole-cell biocatalysis leverages microbial systems to perform complex chemical transformations. For instance, Escherichia coli strains engineered to express cytochrome P450 monooxygenases can carry out regiospecific hydroxylations, a critical modification in the biosynthesis of taxane-based anticancer agents. Additionally, the production of artemisinin analogs, used in malaria treatment, through fermentation processes exemplifies how biocatalysis can circumvent reliance on petrochemical feedstocks, offering a more sustainable approach to API manufacturing.

Despite these advancements, challenges such as enzyme instability under industrial conditions remain. To address this, strategies like immobilizing enzymes on materials such as graphene oxide or metal-organic frameworks (MOFs) have been employed to enhance their thermal resilience. Furthermore, computational tools like Rosetta are now utilized in protein design to generate hyperstable enzyme variants, bridging the gap between laboratory research and commercial application.

Green Chemistry and Catalytic Sustainability

Catalysts are instrumental in advancing active pharmaceutical ingredient (API) manufacturing by adhering to green chemistry principles. They enhance reaction efficiency, enabling the development of new chemical processes that would otherwise be unfeasible. This efficiency not only accelerates production but also reduces the number of steps required to synthesize APIs, thereby minimizing waste generation and energy consumption.

Innovative solvent reduction strategies have been developed to further align with environmental sustainability goals. Techniques such as mechanochemical grinding, which involves the use of catalytic additives, have been employed to eliminate the need for volatile organic compounds (VOCs). This method reduces the reliance on harmful solvents, thereby decreasing the environmental impact of pharmaceutical manufacturing.

Advancements in catalytic processes extend to waste minimization beyond the initial reaction phases. For instance, photocatalytic degradation systems utilizing titanium dioxide have been implemented to break down API effluents into harmless compounds, effectively addressing issues related to aquatic toxicity. This approach ensures that pharmaceutical waste is treated responsibly, reducing its environmental footprint.

Life-cycle assessments have highlighted the environmental benefits of catalytic hydrogenations. These processes facilitate the conversion of agricultural waste into valuable drug precursors, thereby reducing the overall carbon footprint of pharmaceutical production. By upcycling waste materials, the industry not only conserves resources but also promotes a circular economy.

Regulatory frameworks and environmental, social, and governance (ESG) investor expectations are increasingly influencing the adoption of sustainable practices in pharmaceutical manufacturing. The FDA’s Quality by Design (QbD) framework, for example, encourages the intensification of catalytic processes to reduce waste generation. In response, companies are developing “green indices” that quantify solvent and energy savings, transforming sustainability into a competitive metric within the industry.

Future Frontiers: AI, Quantum Catalysts, and Beyond

Artificial intelligence (AI) is transforming catalyst discovery by enabling the identification of novel catalytic materials through advanced computational methods. Machine learning algorithms analyze extensive datasets to predict effective catalyst structures, thereby accelerating the development process.

Generative adversarial networks (GANs), a subset of AI, have been employed to propose innovative metal-ligand combinations. These AI-generated hypotheses are subsequently validated using automated high-throughput screening techniques, enhancing the efficiency of catalyst development.

A notable application of AI in catalysis is the design of catalysts for Suzuki-Miyaura coupling reactions. In certain instances, AI-designed catalysts have demonstrated superior performance compared to traditional human-designed counterparts, achieving higher yields and turnover numbers.

In the realm of nanotechnology, single-atom catalysts (SACs) represent a significant advancement. These catalysts consist of isolated metal atoms dispersed on support materials, maximizing atom efficiency. For example, SACs featuring individual platinum atoms anchored on carbon nitride have been developed for the catalytic reduction of nitro compounds, a key step in synthesizing antibiotic intermediates. This configuration achieves near-theoretical atom utilization, enhancing catalytic efficiency.

Furthermore, the unique properties of graphene-based catalysts are being explored for their potential in facilitating quantum tunneling effects. These effects could enable processes such as room-temperature nitrogen fixation, which is crucial for the production of amine-based active pharmaceutical ingredients (APIs).

The integration of biocatalysis and synthetic biology is paving the way for programmable API synthesis. By utilizing CRISPR gene-editing technology, yeast strains can be engineered to produce terpenoid precursors through designed catalytic cascades. This approach effectively merges fermentation processes with chemical synthesis, offering a versatile platform for API production.

As these innovative methodologies continue to evolve, catalysis remains a cornerstone in advancing pharmaceutical manufacturing. The ongoing development of AI-driven catalyst design, nanotechnology applications, and synthetic biology techniques contributes to creating more sustainable, efficient, and accessible pharmaceutical processes.

Engr. Dex Marco Tiu Guibelondo, B.Sc. Pharm, R.Ph., B.Sc. CpE

Subscribe

to get our

LATEST NEWS

Related Posts

Manufacturing & Logistics

Streamlining Pharmaceutical Synthesis: The Science of Process Intensification in High-Yield API Production

As the industry embraces QbD, PAT, and Pharma 4.0, process intensification will redefine the future of pharmaceutical manufacturing.

Manufacturing & Logistics

Modern Supply Chain Dynamics: Integrating Real-Time Logistics with Blockchain Technology

The convergence of real-time logistics systems and blockchain technology is still in its nascent stages, but the trajectory is promising.

Read More Articles

Myosin’s Molecular Toggle: How Dimerization of the Globular Tail Domain Controls the Motor Function of Myo5a

Myo5a exists in either an inhibited, triangulated rest or an extended, motile activation, each conformation dictated by the interplay between the GTD and its surroundings.