In the high-stakes world of pharmaceutical innovation, where clinical trials can determine the success or failure of life-saving drugs, the optimization of multi-tier supplier networks plays a transformative role. From securing raw materials for drug formulations to ensuring regulatory compliance, an optimized supply chain underpins the efficiency, resilience, and sustainability of the clinical trial process.

This article explores the integration of multi-tier supplier strategies into clinical trials, spotlighting their critical impact on research timelines, cost management, and the global race to develop new therapies.

The Complexity of Clinical Trial Supply Chains

The clinical trial supply chain is among the most intricate in modern industries. It involves a network of suppliers, manufacturers, and logistics providers working together to ensure the seamless delivery of trial materials to global study sites.

Raw Material Sourcing and Multi-Tier Dependencies

The production of pharmaceuticals for clinical trials involves an intricate supply chain network, necessitating the acquisition of active pharmaceutical ingredients (APIs) and excipients from a multi-tier hierarchy of suppliers. Tier 1 suppliers typically provide refined APIs directly used in drug formulation, while Tier 2 and Tier 3 suppliers contribute essential precursors and raw materials, such as chemical intermediates and base compounds. Ensuring the quality, consistency, and uninterrupted availability of these materials at every tier is paramount to maintaining the integrity of clinical trials, as any deviation in material properties can lead to variability in drug performance, compliance issues, or delays in study timelines.

Manufacturing and Packaging Considerations

The manufacturing and packaging processes for clinical trial drugs must be meticulously designed and executed to align with the unique pharmacological and stability profiles of experimental compounds. This involves precise coordination with Tier 2 and Tier 3 suppliers to develop and procure custom materials, such as specialized inert containers for chemically sensitive formulations or advanced temperature-controlled packaging to preserve the bioavailability of biologics. Additionally, adherence to stringent regulatory requirements necessitates thorough documentation and validation of these processes, ensuring that each stage complies with Good Manufacturing Practices (GMP) and meets the expectations of global regulatory bodies.

Global Distribution Challenges

Conducting clinical trials across international sites introduces significant logistical complexities, including managing diverse customs regulations, ensuring compliance with country-specific import/export requirements, and maintaining the integrity of investigational products during transit. These challenges are compounded by the need for real-time coordination and communication across all tiers of the supply chain to address potential disruptions proactively. Advanced tracking systems, robust contingency planning, and collaboration with logistics experts ensure the timely delivery of investigational drugs, enabling trials to proceed without interruption and fostering confidence in the study’s reliability and validity.

Optimizing Supplier Networks to Accelerate Clinical Timelines

Delays in clinical trials can lead to skyrocketing costs and missed opportunities to address urgent medical needs. Multi-tier supplier optimization is critical for streamlining processes and minimizing delays.

Supply Chain Mapping for Critical Components

The process of mapping the supply chain for clinical trials necessitates a comprehensive evaluation of all suppliers and their contributions to the production of trial materials, encompassing active pharmaceutical ingredients (APIs), excipients, and ancillary components such as packaging. Pharmaceutical companies must meticulously trace the supply chain, starting from the investigational drug, to identify potential vulnerabilities, including dependencies on single-source suppliers for critical components or regions prone to geopolitical instability. By implementing strategic diversification measures, such as engaging secondary suppliers or establishing buffer stock inventories, organizations mitigate the risk of disruptions that could lead to production bottlenecks, delayed trials, or compromised data integrity, all of which are critical to maintaining the viability of clinical research programs.

Real-Time Data for Adaptive Decision-Making

The adoption of advanced data integration and analytics platforms enables real-time visibility into the performance, inventory levels, and operational health of suppliers across multiple tiers. These systems employ predictive analytics to proactively identify potential disruptions, such as a Tier 2 supplier experiencing raw material shortages or logistical delays, and provide actionable insights to activate contingency plans. For instance, companies can dynamically adjust procurement strategies, prioritize alternative manufacturing schedules, or allocate resources to maintain the seamless progression of clinical trials. Such adaptive decision-making mechanisms not only ensure continuity but also optimize resource utilization while adhering to stringent timelines and regulatory compliance standards.

Collaborative Supplier Agreements

Establishing collaborative and mutually beneficial agreements with suppliers forms the cornerstone of a resilient and efficient clinical trial supply chain. These partnerships often include joint quality assurance protocols, such as harmonized quality audits to ensure compliance with Good Manufacturing Practices (GMP), as well as shared research and development initiatives aimed at innovating supply chain processes. Additionally, co-investments in infrastructure, such as advanced storage facilities or customized logistics solutions, align supplier capabilities with the specific requirements of investigational drug trials. By fostering trust and shared objectives, these agreements enable pharmaceutical companies to meet critical milestones without sacrificing quality, regulatory adherence, or patient safety.

Risk Mitigation in Pharmaceutical Supply Chains

The stakes for supply chain failures are exceptionally high in clinical trials, where delays or disruptions can derail progress and erode patient trust. Multi-tier supplier management mitigates these risks through strategic foresight and adaptability.

Ensuring Regulatory Compliance Across Tiers

The maintenance of stringent regulatory compliance across all supplier tiers in the pharmaceutical supply chain requires a comprehensive and proactive approach to auditing and monitoring. Pharmaceutical companies must extend their compliance oversight beyond direct Tier 1 suppliers to include indirect Tier 2 and Tier 3 vendors, ensuring that all materials and components meet the necessary regulatory standards such as Good Manufacturing Practices (GMP) and International Council for Harmonisation (ICH) guidelines. This involves conducting detailed on-site audits, reviewing supplier certifications, and validating adherence to environmental, safety, and quality protocols. Any lapse in regulatory compliance, even at lower tiers, can cascade into significant consequences, such as production halts, trial delays, or even the issuance of costly product recalls, severely undermining the integrity and timeline of clinical trials.

Building Contingency Plans for Disruptions

The complex and global nature of pharmaceutical supply chains makes them highly susceptible to a range of disruptions, from geopolitical tensions and natural disasters to unforeseen raw material shortages or logistical bottlenecks. To mitigate these risks, companies must adopt a multifaceted strategy that includes diversifying supplier networks to prevent over-reliance on a single source, maintaining safety stock levels to buffer against sudden shortages, and developing robust contingency plans with predefined escalation protocols. These plans should leverage predictive analytics to forecast potential disruptions and incorporate collaborative agreements with logistics providers to ensure agility and responsiveness. By doing so, organizations can safeguard supply continuity and ensure that critical investigational drugs are delivered to clinical trial sites without interruption.

Addressing Counterfeit and Substandard Materials

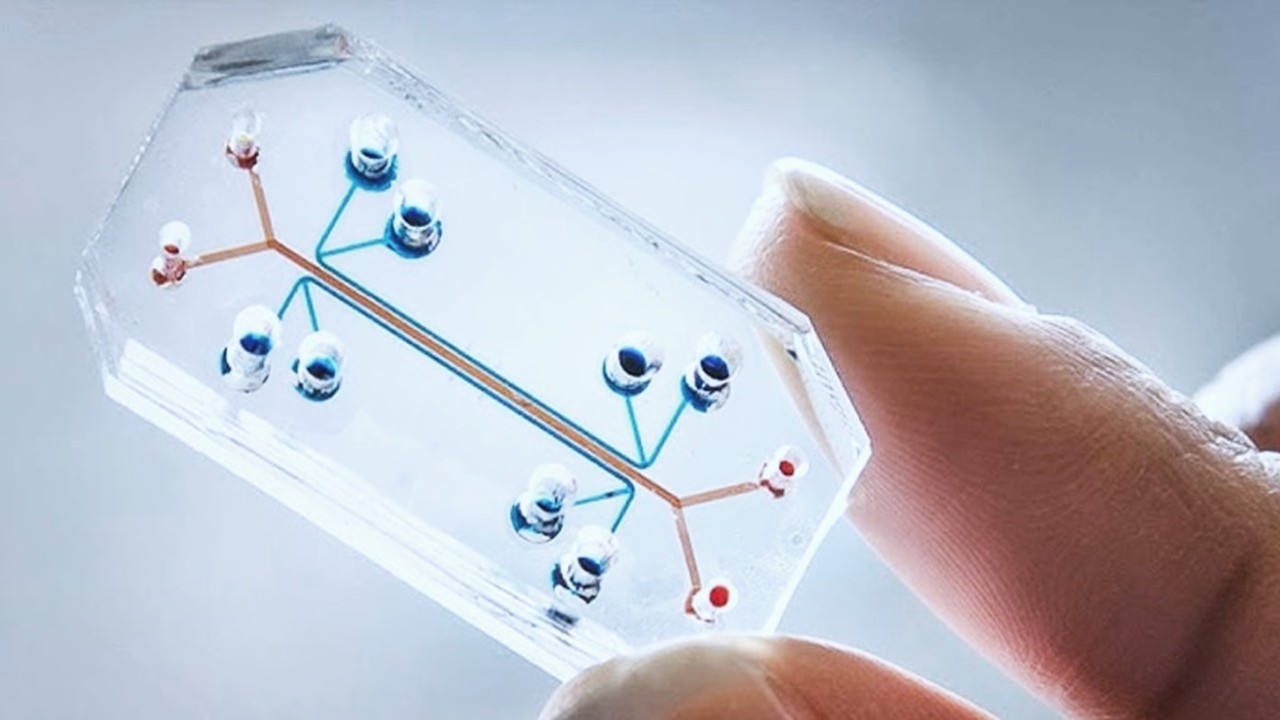

The globalization of pharmaceutical supply chains, while enhancing accessibility and efficiency, has also heightened the risk of counterfeit or substandard materials infiltrating the pipeline. To combat this, advanced tracking and traceability technologies, such as blockchain and Internet of Things (IoT)-enabled sensors, are increasingly being integrated into supply chain systems. Blockchain, in particular, offers a decentralized and tamper-proof ledger that can record every transaction and transfer of materials, enabling real-time verification of authenticity and compliance at every stage from source to end-user. Combined with rigorous testing protocols and supplier verification processes, these technologies ensure the integrity of the supply chain, protecting both the quality of investigational products and the safety of clinical trial participants.

Technological Integration for Streamlined Clinical Supply Chains

Digital tools are revolutionizing the management of multi-tier supplier networks in clinical trials, enabling unprecedented levels of efficiency, accuracy, and adaptability.

Leveraging Blockchain for Traceability

Blockchain technology has emerged as a transformative tool for enhancing traceability within complex, multi-tiered pharmaceutical supply chains, offering an immutable, decentralized ledger to record and verify every transaction. This transparency is particularly valuable in clinical trials, where the provenance, handling, and quality of raw materials and investigational products must be meticulously documented to comply with stringent regulatory standards. By providing a real-time, tamper-proof record of supply chain activities, blockchain mitigates the risk of counterfeit or substandard materials infiltrating the process, ensures accountability at every stage, and enables swift tracebacks in the event of a quality issue. Additionally, the integration of blockchain with smart contracts automates compliance checks and payment triggers, further streamlining operations and enhancing trust among stakeholders.

AI-Driven Demand Forecasting

The application of artificial intelligence (AI) in demand forecasting has revolutionized how pharmaceutical companies predict and manage material requirements during clinical trials, which are inherently dynamic and subject to unpredictable variables. AI-driven systems leverage machine learning algorithms to analyze vast datasets, including historical trial data, patient enrollment trends, and site-specific variables, to forecast material needs with exceptional accuracy. For instance, fluctuating enrollment rates across geographically dispersed study sites can lead to disparities in material consumption, potentially causing delays or inefficiencies. By dynamically adjusting inventory levels in response to real-time data inputs, AI ensures that clinical trial sites are adequately resourced, minimizing wastage and avoiding stockouts, while also optimizing logistical and financial resources.

Digital Twin Technology for Scenario Planning

Digital twin technology, which creates detailed virtual models of physical supply chains, enables pharmaceutical companies to simulate and analyze a wide range of potential scenarios that could disrupt operations. These digital replicas incorporate real-time data from sensors, enterprise systems, and external variables to mirror the complexities of the actual supply chain, allowing for predictive analysis and risk assessment. By modeling disruptions such as supplier failures, logistical bottlenecks, or regulatory changes, companies can identify vulnerabilities and evaluate the effectiveness of mitigation strategies without impacting real-world operations. This proactive approach not only enhances the resilience and robustness of the supply chain but also ensures that clinical trials proceed uninterrupted, even under challenging or unforeseen conditions.

Sustainability in Clinical Trial Supply Chains

As the pharmaceutical industry strives to reduce its environmental footprint, multi-tier supplier strategies are increasingly incorporating sustainability goals without compromising trial efficiency.

Eco-Friendly Sourcing and Packaging

Pharmaceutical companies are increasingly collaborating with their supply chain partners to integrate eco-friendly practices by sourcing biodegradable materials and implementing sustainable packaging solutions tailored to clinical trial needs. These efforts often involve replacing conventional single-use plastics with recyclable or compostable alternatives, which reduce long-term environmental impact without compromising the integrity or safety of the materials. Furthermore, companies are adopting energy-efficient manufacturing processes, such as optimizing production workflows and using renewable energy sources, to minimize the carbon footprint of packaging operations. These innovations not only align with global environmental standards but also resonate with growing regulatory and societal pressures to demonstrate corporate responsibility in addressing climate change.

Minimizing Transportation Emissions

The optimization of distribution networks has become a pivotal strategy for reducing the carbon footprint associated with clinical trial logistics, given the global scope of trial sites and the time-sensitive nature of investigational drug shipments. By consolidating shipments and strategically grouping trial materials destined for nearby locations, companies can reduce the number of transportation cycles and, consequently, overall emissions. Moreover, prioritizing local suppliers to minimize transport distances and employing eco-friendly options such as electric or hybrid vehicles for delivery further enhance the sustainability of logistical operations. Advanced route optimization technologies also play a role, ensuring that transportation pathways are both energy-efficient and time-effective, while adhering to stringent regulatory requirements for product handling and storage conditions.

Promoting Supplier Sustainability Initiatives

Pharmaceutical companies are taking a proactive role in fostering sustainability across all tiers of their supply chain by incentivizing suppliers to adopt environmentally responsible practices. This often involves establishing clear sustainability benchmarks, such as carbon neutrality targets or waste reduction goals, that suppliers are encouraged to meet through strategic improvements. Additionally, organizations provide technical support to suppliers, including assistance with energy efficiency audits, guidance on implementing renewable energy technologies, and workshops on green manufacturing methods. To further drive these initiatives, companies recognize and reward suppliers who demonstrate exemplary environmental performance through certifications or public acknowledgment, creating a culture of sustainability that permeates every level of the supply chain and contributes to the broader objectives of eco-friendly clinical trials.

Case Study: Transforming a Clinical Trial Supply Chain

Consider a biotechnology company conducting global Phase III trials for a novel oncology drug. The company faced delays due to a Tier 3 supplier’s inability to meet the quality standards for a critical excipient. By implementing a multi-tier supplier optimization strategy, the company turned its supply chain into a competitive advantage.

Proactive Supply Chain Restructuring

The company diversified its supplier base, onboarding secondary suppliers for the excipient and ensuring backup sources for other critical components. This restructuring minimized the risk of future disruptions.

Technology Integration for Improved Visibility

By adopting real-time tracking systems, the company gained full visibility into supplier performance and material flow. This allowed them to identify and address potential issues before they could impact trial timelines.

Green Practices in Manufacturing and Logistics

To align with sustainability goals, the company collaborated with suppliers to adopt energy-efficient manufacturing methods and used eco-friendly transportation for distributing trial materials. These efforts reduced the trial’s carbon footprint while enhancing the company’s reputation for corporate responsibility.

Building Resilient and Sustainable Clinical Supply Chains

The optimization of multi-tier supplier networks is not just a logistical necessity but a strategic imperative for the pharmaceutical industry. In the context of clinical trials, where time, quality, and cost are critical, an optimized supply chain can accelerate the path to market for life-saving therapies.

By embracing technology, fostering collaboration, and committing to sustainability, pharmaceutical companies can create supply chains that are not only efficient and resilient but also aligned with the values of ethical and environmental responsibility. As the industry continues to evolve, the integration of these strategies will shape the future of clinical research and global health innovation.

Engr. Dex Marco Tiu Guibelondo, B.Sc. Pharm, R.Ph., B.Sc. CpE

Subscribe

to get our

LATEST NEWS

Related Posts

Clinical Trial Supply Chain

From Chaos to Control: The Clinical Reinvention of Supply Chain through Data-Driven Infrastructure

In a healthcare landscape increasingly dominated by automation and AI, it’s tempting to see technology as a cure-all.

Clinical Trial Supply Chain

Deciphering the Nexus: Cluster Analysis in Shaping Regional Supply Chain Hubs

Cluster analysis has become instrumental in understanding and optimizing supply chains.

Read More Articles

Myosin’s Molecular Toggle: How Dimerization of the Globular Tail Domain Controls the Motor Function of Myo5a

Myo5a exists in either an inhibited, triangulated rest or an extended, motile activation, each conformation dictated by the interplay between the GTD and its surroundings.