In pharmaceutical logistics, the integrity of biologic products hinges on a meticulously maintained cold chain—a temperature-controlled supply line that preserves the efficacy of these sensitive therapeutics from manufacture to administration. Disruptions in this chain can compromise product quality, leading to significant financial losses and, more critically, potential risks to patient health. Implementing robust risk mitigation strategies is essential to ensure the safe delivery of biologics.

Understanding the Vulnerabilities in the Cold Chain

The cold chain encompasses a series of storage and transportation processes designed to maintain biologics within specific temperature ranges, typically between 2°C and 8°C. However, certain products, such as mRNA vaccines, require ultra-low temperatures, sometimes as cold as -80°C. The complexity of maintaining these conditions across various stages introduces multiple points of vulnerability.

Equipment malfunctions represent a primary risk factor. Failures in refrigeration units, whether due to mechanical issues or power outages, can lead to temperature excursions that degrade biologic products. Regular maintenance and calibration of these units are imperative to prevent such occurrences. Additionally, human error, such as improper handling or incorrect temperature settings, can compromise the cold chain. Comprehensive training programs for personnel involved in the storage and transportation of biologics are essential to mitigate this risk.

Environmental factors also pose significant challenges. Unforeseen events like extreme weather conditions or natural disasters can disrupt transportation routes and storage facilities, leading to temperature deviations. Developing contingency plans that include alternative routes and backup power supplies can help manage these unpredictable variables.

Implementing Advanced Monitoring Systems

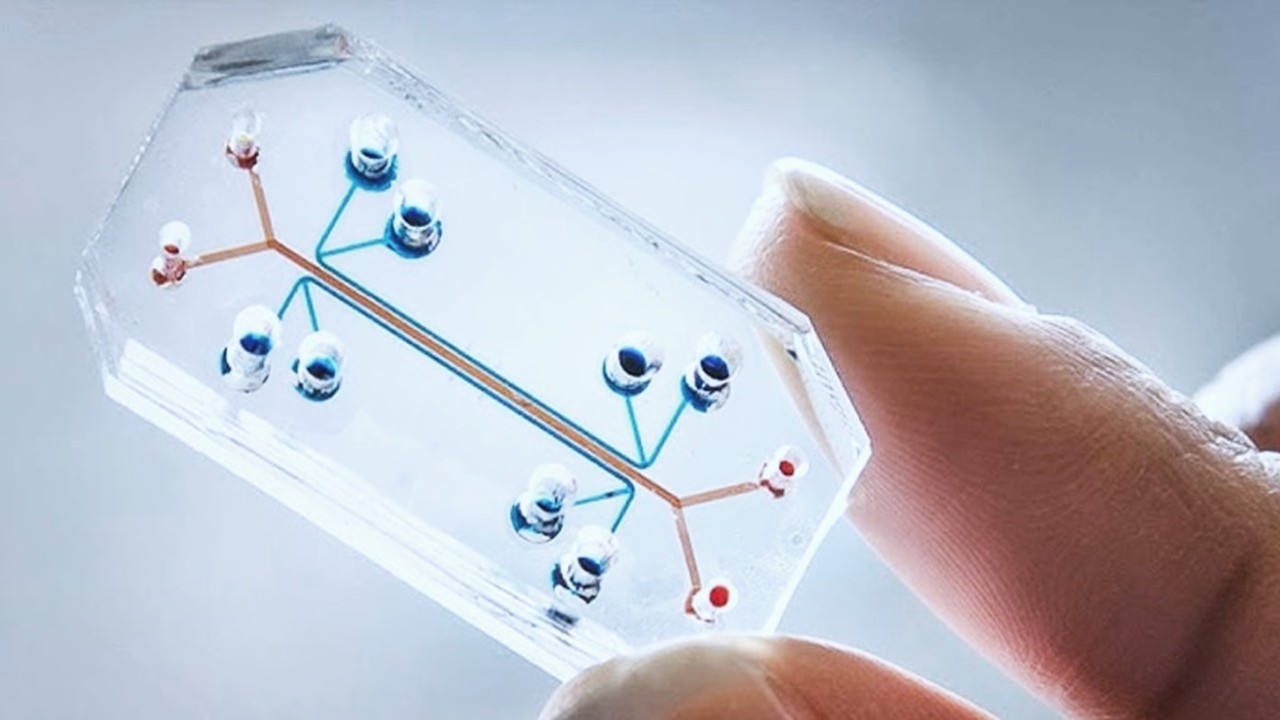

To proactively address potential cold chain failures, the adoption of advanced monitoring technologies is crucial. Real-time temperature tracking devices, such as digital data loggers equipped with buffered temperature probes, provide continuous oversight of product conditions throughout the supply chain. These devices not only record temperature data but also offer alert capabilities to notify stakeholders of excursions, enabling immediate corrective actions.

Integration of Internet of Things (IoT) solutions further enhances monitoring capabilities. IoT-enabled sensors can transmit data in real-time to centralized platforms, allowing for comprehensive visibility and analysis. This connectivity facilitates predictive maintenance by identifying trends that may indicate impending equipment failures, thereby preventing temperature excursions before they occur.

Blockchain technology is emerging as a valuable tool in cold chain management. By providing an immutable ledger of transactions and conditions, blockchain ensures transparency and traceability, which are critical for compliance and quality assurance. Implementing blockchain can enhance trust among stakeholders and streamline the verification processes necessary for regulatory adherence.

Optimizing Packaging Solutions

The selection of appropriate packaging plays a pivotal role in maintaining temperature stability during transit. Advanced thermal insulation materials and phase change materials (PCMs) are employed to design packaging systems that can sustain required temperatures over extended periods, even in the face of external fluctuations.

Passive packaging systems, which do not rely on external power sources, offer reliability and simplicity. These systems utilize materials with high thermal mass to absorb and release energy, thereby maintaining a consistent internal environment. Such solutions are particularly advantageous in regions with unreliable power infrastructure or during long-duration shipments.

Active packaging systems, on the other hand, incorporate battery-powered refrigeration units that provide precise temperature control. While more complex and costly, active systems are suitable for high-value biologics that require stringent temperature maintenance. The choice between passive and active packaging should be guided by factors such as product sensitivity, shipment duration, and environmental conditions.

Enhancing Supply Chain Resilience

Building a resilient supply chain involves strategic planning and collaboration among all stakeholders. Establishing partnerships with logistics providers who have expertise in cold chain management ensures adherence to best practices and regulatory requirements. Regular audits and assessments of these partners can identify potential weaknesses and areas for improvement.

Diversification of transportation modes and routes adds flexibility to the supply chain, reducing dependence on a single pathway that may be susceptible to disruption. Incorporating redundancy, such as multiple storage facilities and backup transportation options, further fortifies the chain against unforeseen events.

Inventory management practices also contribute to resilience. Implementing just-in-time (JIT) inventory systems minimizes the time biologics spend in transit and storage, thereby reducing exposure to potential temperature excursions. However, JIT systems must be balanced with safety stock levels to account for variability in supply and demand.

Sustainable Practices in Cold Chain Management

As the pharmaceutical industry strives for sustainability, integrating eco-friendly practices into cold chain management is gaining prominence. Utilizing energy-efficient refrigeration units and transportation methods reduces the carbon footprint associated with biologics distribution. Renewable energy sources, such as solar-powered refrigeration, offer sustainable alternatives, particularly in remote areas with limited access to conventional power grids.

The adoption of reusable and recyclable packaging materials aligns with environmental sustainability goals. Innovations in packaging design have led to the development of materials that provide necessary thermal protection while being environmentally friendly. Implementing return logistics programs for reusable packaging can further enhance sustainability efforts.

Optimizing transportation routes and consolidating shipments contribute to fuel efficiency and reduced emissions. Advanced route planning software can identify the most efficient paths, taking into account factors such as traffic patterns and weather conditions. Collaborating with logistics providers committed to sustainable practices ensures that environmental considerations are integrated throughout the supply chain.

Regulatory Compliance and Quality Assurance

Ensuring regulatory compliance in biologics cold chain management requires a combination of stringent documentation, real-time monitoring, and adherence to Good Distribution Practices (GDP). Organizations such as the U.S. Food and Drug Administration (FDA), the European Medicines Agency (EMA), and the International Council for Harmonization of Technical Requirements for Pharmaceuticals for Human Use (ICH) have established protocols that define temperature monitoring, data logging, and deviation management requirements. These guidelines set the standard for cold chain logistics, and non-compliance can lead to costly product recalls, legal repercussions, and reputational damage.

A core aspect of quality assurance in biologics logistics is deviation handling. Temperature excursions, even when brief, must be thoroughly investigated to determine their impact on product stability. Root cause analysis techniques, such as Failure Mode and Effects Analysis (FMEA), can be used to identify systemic vulnerabilities and implement corrective actions. Properly calibrated temperature monitoring devices with real-time alerts help companies mitigate deviations before they compromise product quality.

Moreover, audits and validation protocols ensure compliance with regulatory frameworks. Regular internal audits help companies identify inefficiencies in their cold chain logistics, while third-party audits conducted by regulatory agencies provide an external evaluation of adherence to best practices. Qualification of storage units, transport vehicles, and packaging systems must be an ongoing process, as the sensitivity of biologics requires continuous improvements in storage and handling methodologies.

The Future of Biologics Cold Chain Management

Advancements in technology and logistics are shaping the future of biologics cold chain management, with innovations focused on automation, predictive analytics, and enhanced packaging solutions. Artificial intelligence (AI) and machine learning are being integrated into predictive maintenance systems to detect early signs of equipment failure, ensuring that refrigeration units remain operational without interruption. AI-driven logistics platforms can also optimize transportation routes in real-time, reducing the risk of shipment delays and temperature excursions.

Smart packaging solutions are becoming more sophisticated, incorporating nanotechnology and self-regulating temperature control mechanisms. These smart materials can adapt to environmental changes and provide additional layers of protection against thermal fluctuations. Furthermore, developments in synthetic biology may lead to the engineering of biologic products with greater stability at higher temperatures, reducing dependence on ultra-low-temperature storage solutions.

Decentralized manufacturing strategies are also emerging as a way to mitigate risks associated with long-distance transportation. By establishing localized production facilities, pharmaceutical companies can reduce reliance on global supply chains, minimizing the exposure of biologics to transportation-induced temperature fluctuations. This model is particularly relevant in pandemic response scenarios, where rapid distribution of vaccines and biologics is essential.

The biologics industry is at a critical juncture, where efficiency, sustainability, and innovation must converge to build a resilient cold chain infrastructure. By leveraging cutting-edge technology, refining regulatory compliance strategies, and embracing sustainable practices, pharmaceutical companies can safeguard the integrity of biologics and ensure that life-saving therapies reach patients in optimal condition. As cold chain management evolves, the integration of advanced scientific methodologies and logistical precision will be the key to mitigating risks and securing the future of biologics distribution.

Engr. Dex Marco Tiu Guibelondo, B.Sc. Pharm, R.Ph., B.Sc. CpE

Subscribe

to get our

LATEST NEWS

Related Posts

Manufacturing & Logistics

Streamlining Pharmaceutical Synthesis: The Science of Process Intensification in High-Yield API Production

As the industry embraces QbD, PAT, and Pharma 4.0, process intensification will redefine the future of pharmaceutical manufacturing.

Manufacturing & Logistics

Modern Supply Chain Dynamics: Integrating Real-Time Logistics with Blockchain Technology

The convergence of real-time logistics systems and blockchain technology is still in its nascent stages, but the trajectory is promising.

Read More Articles

Myosin’s Molecular Toggle: How Dimerization of the Globular Tail Domain Controls the Motor Function of Myo5a

Myo5a exists in either an inhibited, triangulated rest or an extended, motile activation, each conformation dictated by the interplay between the GTD and its surroundings.