The journey of an Active Pharmaceutical Ingredient (API) from laboratory bench to industrial-scale production is fraught with technical, logistical, and regulatory challenges. Scaling up API synthesis is not a mere matter of increasing quantities; it is a rigorous process that transforms laboratory methods into viable industrial protocols. This intricate endeavor is pivotal in ensuring the timely and cost-effective delivery of high-quality pharmaceuticals to global markets. Below, we explore the multifaceted challenges of API scale-up, delving into its technical, operational, and sustainability dimensions.

Process Development: Optimizing Chemistry for Scale

In laboratory settings, API synthesis focuses on flexibility and feasibility to meet research needs. However, these early-stage methods are often unsuitable for industrial-scale production. For instance, a synthetic route that uses exotic reagents or complex intermediate steps may be cost-prohibitive or environmentally unsustainable when scaled to hundreds or thousands of kilograms. To address this, chemists and engineers engage in process development, a meticulous phase that redesigns synthetic routes for scalability.

Process development involves evaluating several factors, including reaction yields, raw material availability, and operational safety. Key decisions during this phase often involve trade-offs, such as choosing between a high-yield but multistep process versus a streamlined but lower-yield route. Additionally, reaction mechanisms that seem stable at small scales may exhibit unexpected behaviors at larger volumes, such as altered kinetics or byproduct formation. Hence, chemists must reoptimize conditions like temperature, pressure, and catalyst concentrations to achieve consistent results.

A critical aspect of this stage is reproducibility. Inconsistent laboratory methods can lead to batch-to-batch variability, which becomes magnified at scale. This requires chemists to implement rigorous standard operating procedures (SOPs) and ensure all process variables are tightly controlled. Ultimately, process development bridges the gap between exploratory research and reliable industrial-scale synthesis, setting the foundation for further scale-up efforts.

Equipment Engineering: From Glassware to Gigaliter Reactors

One of the most striking challenges in API scale-up is the translation of small-scale reactions into large-scale operations. Laboratory processes often rely on specialized glassware, precise instrumentation, and small reaction volumes that are impractical at industrial scales. Transitioning these reactions into reactors that hold hundreds or thousands of liters introduces a cascade of engineering challenges that demand careful consideration.

Heat and mass transfer inefficiencies often emerge as the most critical issues during scale-up. In a small laboratory flask, mixing and heat dissipation occur efficiently, ensuring uniform reaction conditions. However, in larger reactors, inadequate mixing can lead to temperature gradients, localized reaction hotspots, or incomplete reactions. Similarly, exothermic reactions—easily managed with external cooling in a laboratory—pose serious safety risks when scaled up due to the inability to rapidly dissipate heat.

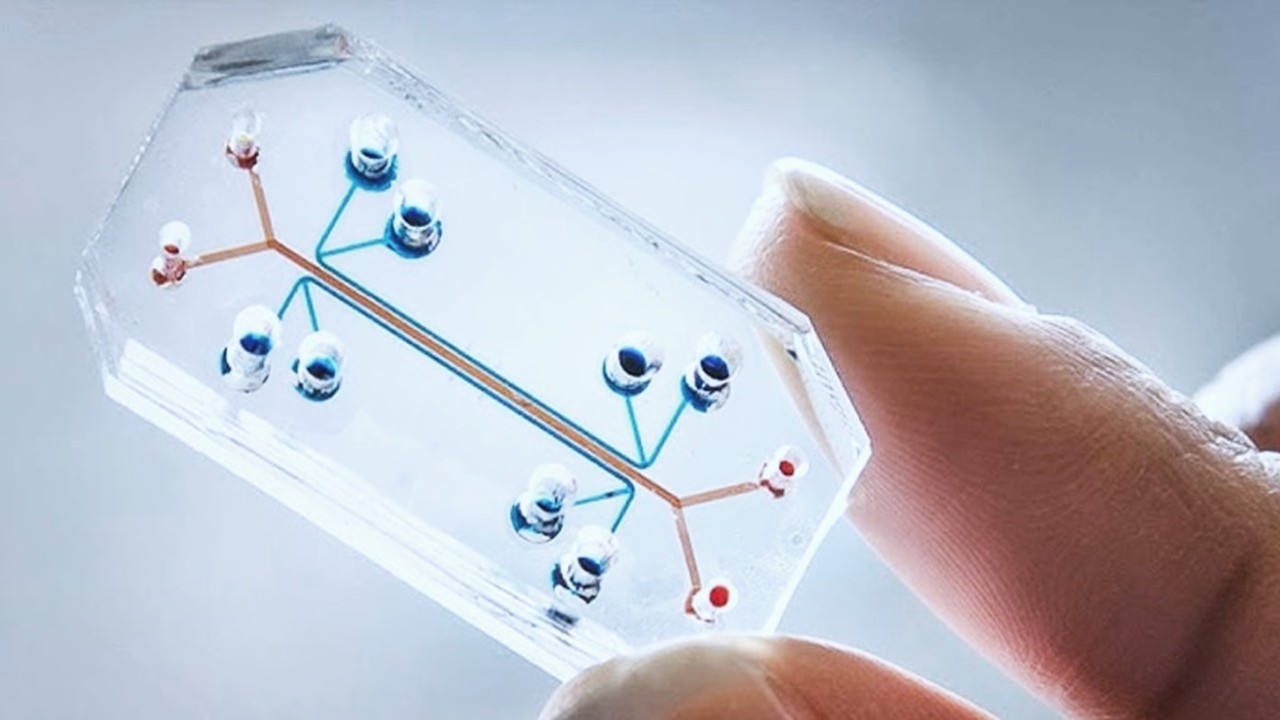

To address these challenges, engineers must redesign reaction systems with industrial equipment in mind. This may involve employing jacketed reactors for efficient heat exchange, using impellers or baffles for improved mixing, and introducing automated controls to monitor critical parameters in real time. Additionally, techniques like continuous flow chemistry are increasingly being explored to bypass the limitations of batch reactors. While these approaches can mitigate scale-up risks, they require extensive testing and validation to ensure compatibility with the API’s synthetic pathway.

Quality Control: Ensuring Purity at Every Scale

API purity is not negotiable; even trace impurities can compromise drug safety, efficacy, or stability. As the scale of production increases, maintaining stringent quality standards becomes exponentially more complex. Each step in the scale-up process—raw material procurement, reaction execution, and product isolation—presents potential risks for contamination or variability.

One key challenge is the amplification of impurities during scaling. Impurities that are negligible at small scales can accumulate to problematic levels when processes are scaled up. For instance, side reactions that produce minute byproducts in a 100-milliliter reaction may result in significant impurities when the same reaction is performed in a 1,000-liter reactor. Addressing this requires robust analytical methods to identify, quantify, and mitigate impurities at every stage of production.

In addition to chemical purity, consistency across batches is critical. Regulatory standards such as Good Manufacturing Practices (GMP) mandate that every batch of an API must meet predefined specifications. Achieving this requires rigorous process validation, where each variable—temperature, pressure, reagent addition rates—is meticulously controlled and documented. Advanced techniques like high-performance liquid chromatography (HPLC), mass spectrometry, and infrared spectroscopy are employed to ensure APIs meet both regulatory and therapeutic standards.

Regulatory Hurdles: Navigating Compliance in Scale-Up

The pharmaceutical industry operates under some of the most stringent regulatory frameworks in the world, and scaling up API synthesis adds layers of complexity to compliance efforts. Regulatory agencies require manufacturers to demonstrate not only the safety and efficacy of their APIs but also the reliability and reproducibility of their production processes. Achieving this involves navigating a maze of requirements, from documentation to validation protocols.

Process validation is a cornerstone of regulatory compliance during scale-up. This involves extensive testing to ensure that the scaled-up process consistently produces APIs within acceptable quality parameters. Each aspect of production, from raw material sourcing to final product packaging, must be thoroughly documented. Any deviations from the validated process can result in production delays, costly investigations, or even regulatory penalties.

Another critical aspect of regulatory compliance is managing environmental and worker safety. Regulatory agencies closely scrutinize the handling of hazardous reagents, waste disposal practices, and energy consumption. Manufacturers must implement strict safety protocols, conduct regular audits, and invest in training programs to ensure compliance. While these measures increase operational complexity, they are essential for protecting both public health and the environment.

Sustainability in Scale-Up: A Green Chemistry Imperative

As the pharmaceutical industry faces mounting pressure to reduce its environmental footprint, integrating sustainability into API scale-up has become a critical priority. Traditional chemical manufacturing processes often rely on toxic solvents, energy-intensive reactions, and inefficient waste management practices. These issues are magnified at industrial scales, where even minor inefficiencies can lead to significant environmental impacts.

Green chemistry offers a pathway to more sustainable API production. This involves designing synthetic routes that minimize waste, avoid hazardous reagents, and optimize energy efficiency. For example, replacing traditional solvents with greener alternatives like water or ethanol can reduce both environmental and safety risks. Similarly, advances in catalysis have enabled more efficient reactions that require lower temperatures and generate fewer byproducts.

Waste reduction is another area of focus. By implementing closed-loop systems and recycling solvents, manufacturers can significantly decrease the volume of chemical waste generated during production. Additionally, adopting continuous flow processes can improve material efficiency and reduce energy consumption compared to traditional batch processes. While these approaches require upfront investment, they offer long-term benefits in terms of cost savings, regulatory compliance, and environmental stewardship.

Converging Innovation and Responsibility

Scaling up API synthesis is a multidisciplinary challenge that demands innovation, precision, and accountability. From optimizing chemical pathways to engineering industrial processes and navigating regulatory landscapes, each step requires careful planning and execution. At its core, the scale-up process is about more than producing APIs at larger volumes—it is about ensuring that these essential compounds are safe, effective, and sustainable.

As the pharmaceutical industry continues to evolve, the integration of green chemistry principles and advanced technologies will be critical in meeting global health needs while minimizing environmental impact. By embracing these innovations, manufacturers can transform the scale-up process into a model of efficiency and sustainability, ultimately advancing both science and society.

Engr. Dex Marco Tiu Guibelondo, B.Sc. Pharm, R.Ph., B.Sc. CpE

Subscribe

to get our

LATEST NEWS

Related Posts

Manufacturing & Logistics

Streamlining Pharmaceutical Synthesis: The Science of Process Intensification in High-Yield API Production

As the industry embraces QbD, PAT, and Pharma 4.0, process intensification will redefine the future of pharmaceutical manufacturing.

Manufacturing & Logistics

Modern Supply Chain Dynamics: Integrating Real-Time Logistics with Blockchain Technology

The convergence of real-time logistics systems and blockchain technology is still in its nascent stages, but the trajectory is promising.

Read More Articles

Myosin’s Molecular Toggle: How Dimerization of the Globular Tail Domain Controls the Motor Function of Myo5a

Myo5a exists in either an inhibited, triangulated rest or an extended, motile activation, each conformation dictated by the interplay between the GTD and its surroundings.