The Evolution of Chemical Synthesis: From Human Intuition to Machine Precision

For centuries, chemical synthesis has relied on the ingenuity and experience of organic chemists to navigate the vast landscape of molecular transformations. The process of retrosynthetic analysis, introduced in the 1960s, revolutionized the way chemists approached complex molecule construction by systematically deconstructing target compounds into simpler precursors. Yet, despite the advancements in synthetic planning, the process remained an intricate art—highly dependent on human expertise, trial-and-error experimentation, and heuristic-driven decision-making.

The integration of computational methods into chemical synthesis marked a turning point in the field. Early attempts at algorithmic retrosynthetic analysis, such as the LHASA system, sought to encode human knowledge into rule-based programs. Over time, cheminformatics and machine learning introduced more sophisticated, data-driven models capable of predicting reaction pathways, ranking synthetic routes, and even suggesting novel transformations beyond human intuition.

Today, deep neural networks and AI-driven retrosynthesis tools are redefining synthetic pathway design. Algorithms can now navigate reaction networks with unprecedented efficiency, identifying optimal routes for chemical synthesis while minimizing costs, environmental impact, and synthetic complexity. As computational power continues to advance, the role of AI in chemical synthesis is shifting from an auxiliary tool to an indispensable partner in molecular discovery.

From Rule-Based Systems to AI: The Computational Revolution in Retrosynthesis

The earliest computational retrosynthesis models were built on explicit rule-based systems that mimicked the logic used by organic chemists. Systems like LHASA and SYNLMA encoded vast libraries of known chemical transformations, applying predefined heuristics to suggest plausible synthetic routes. These programs, while groundbreaking for their time, struggled with two major limitations: the inability to generalize beyond their rule sets and the challenge of maintaining comprehensive, up-to-date reaction databases.

The next phase in computational retrosynthesis saw the emergence of network-based approaches. Programs like Chematica utilized massive reaction databases to construct expansive graphs of organic transformations, allowing researchers to explore synthetic pathways algorithmically. Instead of following a fixed rule set, these systems employed heuristic search techniques, such as Monte Carlo tree search and cost-minimization algorithms, to identify the most efficient synthesis routes. By considering reaction costs, substrate availability, and purification requirements, network-searching models provided more practical retrosynthetic solutions.

However, even these advances fell short in handling the full complexity of chemical reactions. Organic synthesis is filled with exceptions, stereochemical constraints, and reactivity conflicts that are difficult to encode into fixed rules. Recognizing these limitations, researchers turned to machine learning, marking a paradigm shift in computational chemical synthesis.

Machine Learning and the Two-Step Approach to Retrosynthesis

Machine learning has transformed retrosynthetic analysis by introducing probabilistic and data-driven decision-making processes. Instead of rigidly following predefined rules, AI models learn from vast datasets of known reactions to infer likely transformations. The earliest ML-driven retrosynthetic models followed a two-step approach:

Reaction Rule Extraction: Algorithms first identified generalizable reaction rules from databases like Reaxys and SciFinder. These rules served as the foundation for proposing synthetic routes.

Probability-Based Selection: Once possible transformations were generated, machine learning models ranked them based on statistical likelihood, prioritizing those with the highest confidence scores.

Programs such as ARChem Route Designer exemplified this hybrid approach, replacing hand-coded reaction heuristics with automatically extracted reaction rules. Later models, including those developed by Coley et al., refined this concept by using deep learning techniques to optimize reaction predictions. By integrating neural networks with cheminformatics databases, AI could rapidly propose reaction pathways while factoring in stereoelectronic effects, regioselectivity, and chemoselectivity.

Despite these improvements, rule-based and two-step AI models still required substantial human oversight. They struggled with reaction conditions, stereochemistry, and unknown transformations that fell outside their training datasets. To overcome these limitations, researchers turned to fully end-to-end deep learning models capable of retrosynthetic analysis without predefined rules.

Deep Learning in Synthetic Chemistry: A Fully Data-Driven Approach

Recent advances in deep learning have introduced end-to-end AI models that require no human-defined reaction rules. Instead of relying on encoded heuristics, these models treat chemical reactions as language translation problems—converting reactants into products using neural network architectures originally designed for machine translation.

Seq2seq (sequence-to-sequence) models, a type of deep learning architecture, have proven particularly effective in reaction prediction and retrosynthesis. By representing molecules as SMILES (Simplified Molecular Input Line Entry System) strings, these models learn reaction patterns in a manner analogous to how neural networks process natural language. Given a target molecule, a seq2seq model can generate plausible precursor structures with remarkable accuracy.

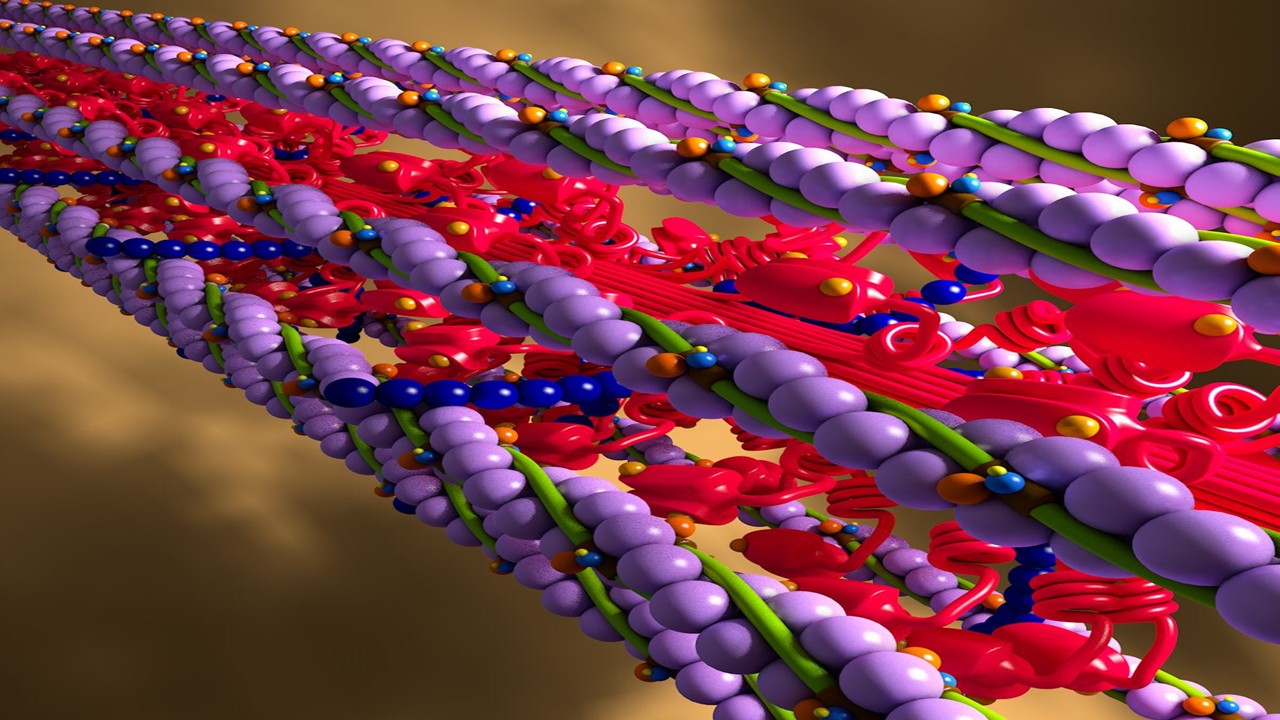

Other deep learning approaches have taken this further by leveraging graph neural networks (GNNs), which model molecules as node-edge representations rather than linear strings. The Weisfeiler-Lehman Network (WLN) approach, for example, identifies reaction centers within molecular graphs, allowing AI to predict transformations at an atomic level. This method has demonstrated superior accuracy in predicting unknown reactions, as it captures subtle molecular interactions that traditional retrosynthetic models might overlook.

These end-to-end models have propelled AI-driven retrosynthesis to new heights. By eliminating the need for human-defined reaction rules, deep learning approaches enable AI to explore chemical space more freely, identifying unconventional synthesis pathways that might escape even the most experienced organic chemists.

Automating Synthesis Pathways: The Future of AI in Chemical Manufacturing

As AI-driven retrosynthesis continues to evolve, its impact extends beyond theoretical synthetic planning. Automated synthesis platforms are now integrating AI models to streamline chemical production, reducing human intervention and increasing efficiency.

Robotic synthesis laboratories, such as MIT’s Chemputer, utilize AI algorithms to design and execute multi-step organic syntheses autonomously. These systems combine AI-driven retrosynthetic planning with automated flow chemistry, enabling continuous production of complex molecules with minimal human oversight. By optimizing reaction conditions in real time, AI-powered synthesis robots can dynamically adjust reaction parameters to maximize yields and minimize side reactions.

Beyond laboratory automation, AI-driven retrosynthesis is also revolutionizing drug discovery and materials science. Pharmaceutical companies now employ AI models to rapidly explore synthetic routes for new drug candidates, significantly reducing the time required for lead optimization. In materials science, AI-guided synthesis is accelerating the development of next-generation polymers, catalysts, and electronic materials by efficiently identifying optimal synthetic pathways.

Challenges and Future Directions in AI-Driven Retrosynthesis

Despite its advancements, AI-driven retrosynthesis still faces several challenges that must be addressed to fully realize its potential:

Stereochemistry and Regioselectivity: While deep learning models excel at predicting bond rearrangements, they often struggle with stereochemical control. Developing AI systems that can accurately predict stereoselective reactions remains a major hurdle.

Reaction Condition Optimization: Current models focus primarily on reaction transformations rather than the conditions required to achieve them. AI must advance beyond predicting reactants and products to optimizing catalysts, solvents, temperatures, and pressure conditions.

Handling Negative Data: Most reaction databases contain only successful transformations, making it difficult for AI models to learn what doesn’t work. The incorporation of negative reaction data is crucial for improving prediction accuracy.

Expanding Beyond Known Chemistry: AI models are largely trained on existing reaction datasets, limiting their ability to propose truly novel transformations. Enhancing AI’s ability to extrapolate beyond known chemistry will be essential for discovering new synthetic methodologies.

As computational power increases and AI algorithms become more sophisticated, these challenges will be progressively overcome. The future of AI-driven retrosynthesis lies in hybrid models that combine machine learning with quantum chemistry simulations, enabling more precise reaction predictions at the atomic level.

The AI-Powered Chemist: A New Era of Molecular Innovation

AI-driven retrosynthetic analysis is no longer a speculative vision—it is a rapidly advancing reality that is reshaping the way chemists approach molecular synthesis. From network-based reaction searching to deep learning-powered retrosynthesis, AI has evolved into a powerful tool capable of rivaling human expertise in synthetic planning.

As AI continues to refine its predictive accuracy and expand its capabilities, its role in chemical discovery will only grow. The next generation of computational chemists will not merely use AI as a tool but will collaborate with machine-learning systems as co-researchers, pushing the boundaries of synthetic chemistry into uncharted territories.

With AI leading the charge, the future of chemical synthesis promises to be faster, more efficient, and more innovative than ever before.

Study DOI: 10.3389/fchem.2018.00199

Engr. Dex Marco Tiu Guibelondo, B.Sc. Pharm, R.Ph., B.Sc. CpE

Subscribe

to get our

LATEST NEWS

Related Posts

Medicinal Chemistry & Pharmacology

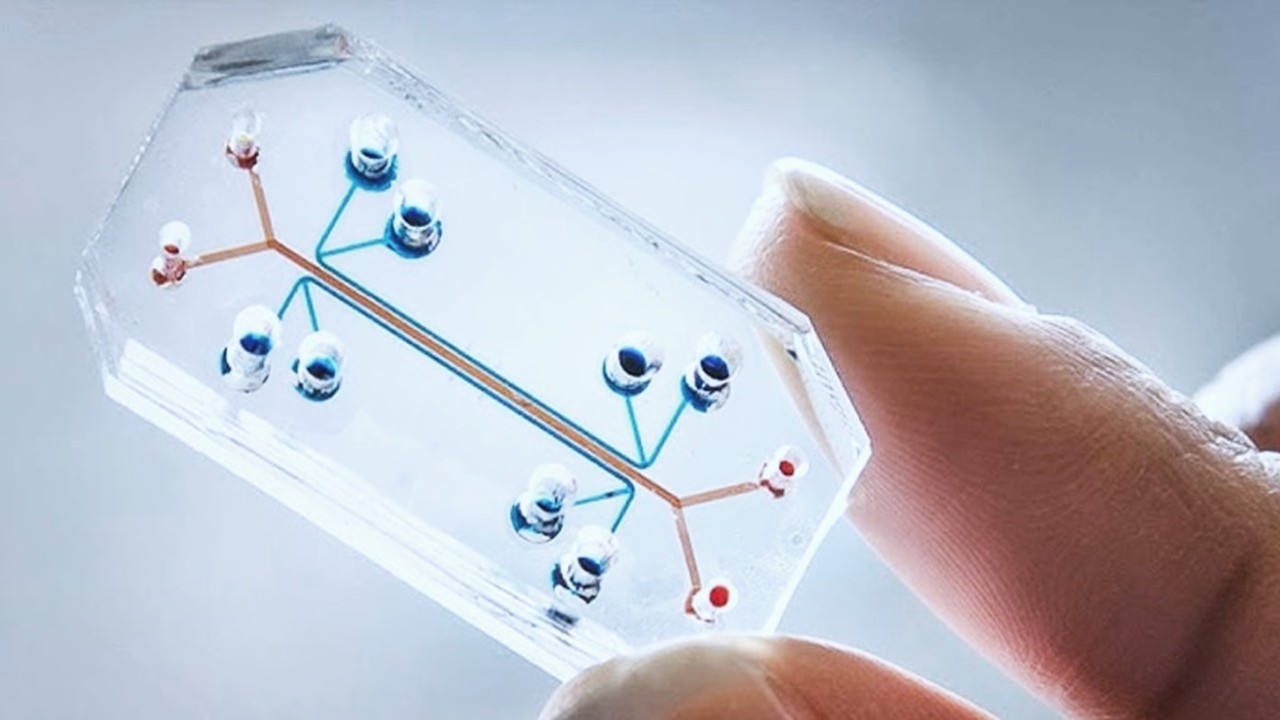

Invisible Couriers: How Lab-on-Chip Technologies Are Rewriting the Future of Disease Diagnosis

The shift from benchtop Western blots to on-chip, real-time protein detection represents more than just technical progress—it is a shift in epistemology.

Medicinal Chemistry & Pharmacology

Designing Better Sugar Stoppers: Engineering Selective α-Glucosidase Inhibitors via Fragment-Based Dynamic Chemistry

One of the most pressing challenges in anti-diabetic therapy is reducing the unpleasant and often debilitating gastrointestinal side effects that accompany α-amylase inhibition.

Medicinal Chemistry & Pharmacology

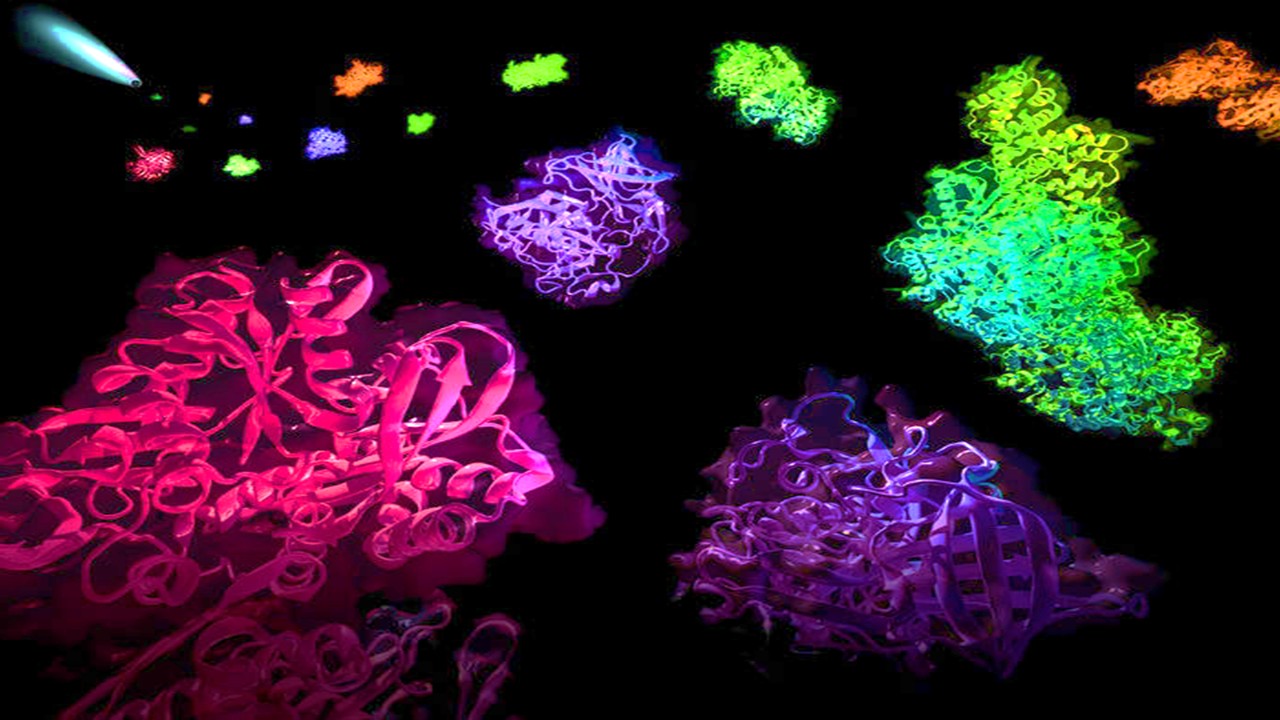

Into the Genomic Unknown: The Hunt for Drug Targets in the Human Proteome’s Blind Spots

The proteomic darkness is not empty. It is rich with uncharacterized function, latent therapeutic potential, and untapped biological narratives.

Medicinal Chemistry & Pharmacology

Aerogel Pharmaceutics Reimagined: How Chitosan-Based Aerogels and Hybrid Computational Models Are Reshaping Nasal Drug Delivery Systems

Simulating with precision and formulating with insight, the future of pharmacology becomes not just predictive but programmable, one cell at a time.

Read More Articles

Myosin’s Molecular Toggle: How Dimerization of the Globular Tail Domain Controls the Motor Function of Myo5a

Myo5a exists in either an inhibited, triangulated rest or an extended, motile activation, each conformation dictated by the interplay between the GTD and its surroundings.